ViveLab Ergo

Ergonomic verification in 3D virtual space

ViveLab Ergo is a product of ViveLab Ergo Ltd.

ViveLab Ergo is a product of ViveLab Ergo Ltd.

ViveLab Ergo is a high-performance cloud computing innovative simulation system that is perfectly capable of modeling machines, robots and people moving in a given physical environment. Harmonizing the co-operation of these three elements in the industry's 4.0 era is an indispensable task. Using an anthropometric database containing millions of samples, it precisely models ninety-nine percent of human population's anthropometrical characteristics. It highlights the health-damaging effects of forced movements caused by incorrect workplace design using 7 built-in ergonomic analyzes: RULA, OWAS, NASA-OBI, ISO 11226, EN 1005-4, reachability zone, spaghetti diagram.

This technology can be used to ergonomic improvement of existing workstations, ergonomic design of new workstations, or ergonomic design of products. The user-friendly interface has been designed considering the most modern ergonomic viewpoints, which ensures that design engineers, work safety managers, HR specialists, or even creative designers can independently run or collaboration a team to run and evaluate simulations logging in from anywhere in the world.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This article discusses the use of moving particle simulation of the oil distribution system to predict heat dissipation and temperature distribution in the engine in order to examine virtual e-drive prototypes to improve their final design.

particleworks automotive

CASE STUDY

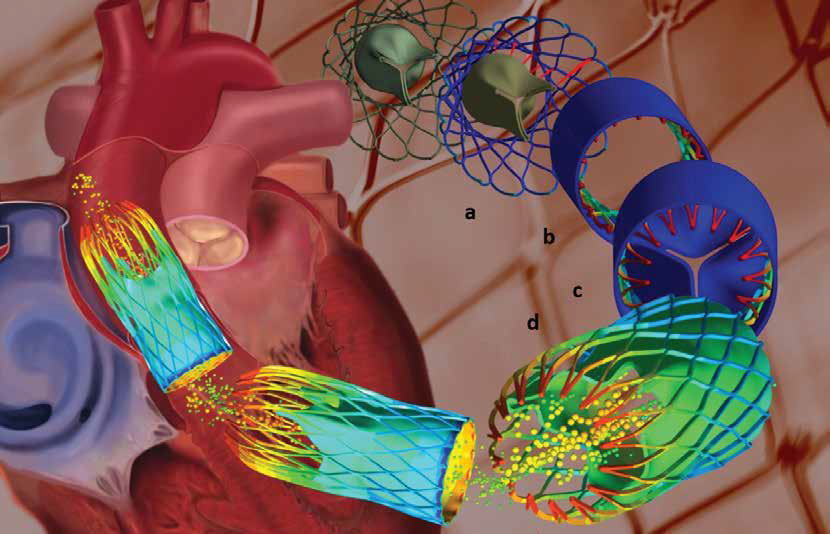

This technical article describes how high-end numerical Computational Fluid Dynamics (CFD) simulations were applied to mimic the realistic operating conditions of a Ventricular Assist Device (VADs) and analyze its hemodynamics in order to identify potential areas for optimization of the device’s performance, safety and efficacy.

ansys cfd biomechanics

Our competences in ViveLab Ergo

CASE STUDY

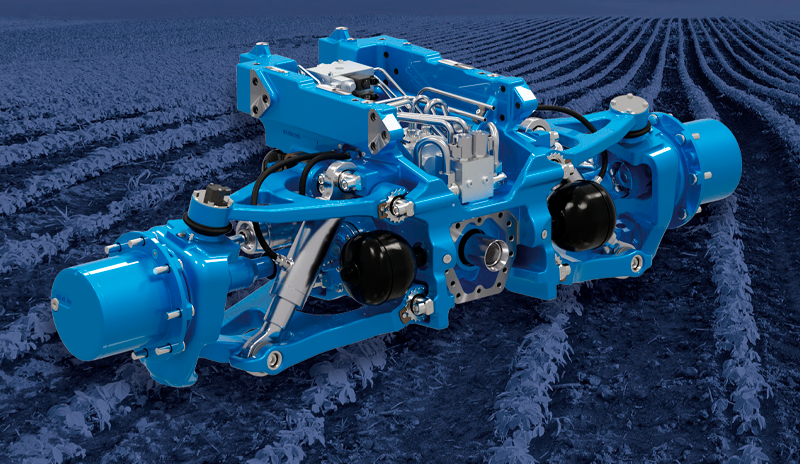

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization

CASE STUDY

Since this cannot be accurately measured in an implanted stent, manufacturers decided to use Multiphysics to simulate the process to better understand the method and to calculate the forces operating on the implant in order to improve the stent design and the surgical procedure, as described in this article.

cfd biomechanics ansys

CASE STUDY

This article describes how EnginSoft supported Metasystem in acquiring the know-how to satisfy future customer requests on the one hand, and to create projects that are as profitable as possible in terms of waste minimization, on the other hand.

automotive tolerances cetol