TwinMesh

A revolutionary meshing solution for reliable CFD analysis of rotary positive displacement machines

TwinMesh is a product of CFX Berlin Software GmbH.

TwinMesh is a product of CFX Berlin Software GmbH.

Thanks to TwinMesh software, computational fluid dynamics (CFD) has become an efficient development tool for the first time also for manufacturers of rotary positive displacement machines.

An important prerequisite for reliable CFD simulations, is the creation of high-quality meshes that mimic the computational domain as precisely as possible, without increasing too much the model number of elements.

The creation of such computational domain poses two significant challenges for engineers when working with rotary pumps, gear pumps and screw compressors. The complexity of the geometry of rotary positive displacement machines results from the flow volumes in the working chambers which vary over time. The second challenge are the extremely small gaps between the rotors and between the rotors and the housing.

With the help of meshing software TwinMesh, the time-varying flow volumes and gaps in the working space of volumetric machines can be automatically meshed with high-quality structured hexahedral meshes, for a number of angular positions specified by the user. By using a smoothing algorithm contained in TwinMesh, the node distributions always remain homogeneous, and the interior element angle remains nearly orthogonal.

TwinMesh provides also special templates for all typical displacement machines, taking care of the actual simulation setup, monitoring and post-processing in ANSYS CFX simply pressing a button.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

Traditional naval architecture meets the CFD analysis with the aim to improve consolidated products reaching values in terms of performance never seen before.

ansys cfd marine

CASE STUDY

This study discusses the complex and challenging problem of controlling vortex-induced vibrations (VIV).

cfd mechanics ansys rbf-morph

Our competences in TwinMesh

CASE STUDY

This article presents a study that the Elica Group commissioned from EnginSoft to support it engineering team in redesigning the ventilation system of its “Tilly” kitchen hood model

appliances ansys cfd

CASE STUDY

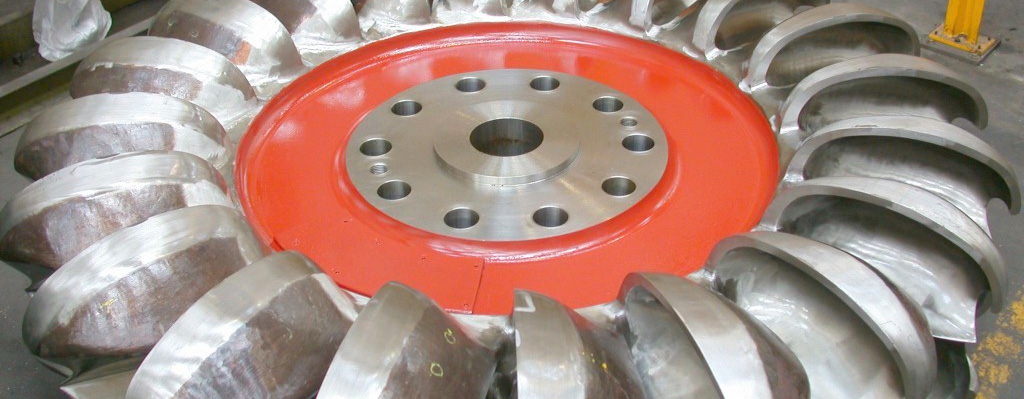

EnginSoft developed a Computational Fluid Dynamic (CFD) analysis methodology for the performance evaluation of a Pelton turbine

energy cfd ansys oil-gas

CASE STUDY

In this interview, engineer Luca Cavalli, of Immergas’ advanced engineering team, discusses the technical and business benefits the company has realised since first introducing Computer-Aided Engineering (CAE) technologies into its R&D department in 1997.

ansys appliances cfd mechanics

CASE STUDY

This case study details the design optimization of an axial steam turbine of 160 MW, focusing on maximizing the total-to-total isentropic efficiency of the last three low-pressure stages of the turbine.

cfd ansys turbomachinery modefrontier

CASE STUDY

EnginSoft developed a 3D CFD model of a Liquefied Natural Gas (LNG) Plant for the simulation of the Air-Cooled Heat Exchanger Systems’ (ACHE) arrays and their interaction with the wind.

energy cfd ansys oil-gas

CASE STUDY

In this technical article, a CFD study of various designs for four different specialty tractors: two brands of specialty tractors for vineyard configurations, and two brands of specialty tractors for orchard configurations, are described.

automotive ansys cfd

CASE STUDY

Motorsport’s competitive demands drive innovation, such as optimizing fuel tank performance by reducing sloshing and ensuring efficient fuel extraction. This study explores a meshless CFD approach using Moving Particle Simulation (MPS) to streamline workflows and reduce computational costs compared to traditional finite volume method (FVM) CFD.

automotive cfd particleworks

CASE STUDY

The car is designed to race on the ultra-flat Salt Flats in Bonneville, Utah. The racecar weighs less than 500kg so increasing the downforce was critical. Reducing aerodynamic drag was also critical due to the power requirements of the racecar.

cfd automotive

CASE STUDY

The objective of the study was to create a virtual model of Climaveneta’s new ACU171 Expanded Close Control Unit and then match the numerical results with the experimental measures.

cfd ansys appliances

CASE STUDY

This technical article, a collaboration between EnginSoft and ZECO, compares two different methodologies for the study and optimization of impulse turbines, specifically Pelton turbines, in order to evaluate which is the quicker and more reliable method.

cfd particleworks energy

CASE STUDY

EnginSoft implemented a new 3D CFD multi-phase model to simulate the water condensation-evaporation processes inside automotive headlamps for Automotive Lighting, a leading supplier of quality headlights to the OEM market

automotive cfd ansys rail-transport

CASE STUDY

GE Power is a world leading supplier of solutions for power generation, from engineering to manufacturing. Detecting and mitigating critical flow structures in water pumping stations is a complex engineering task, that has always been based on experimental activities. Now GE Power can rely also on CFD modelling and on the support of EnginSoft

ansys cfd energy

CASE STUDY

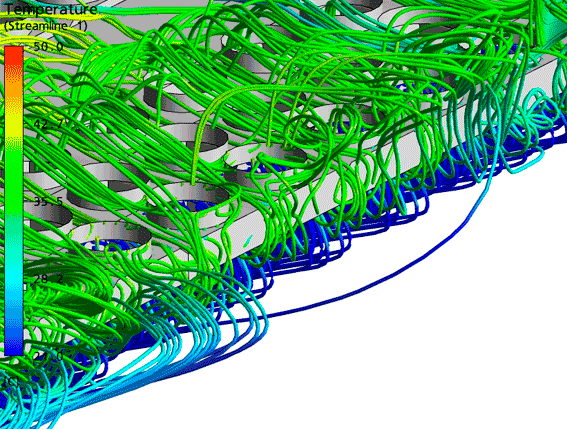

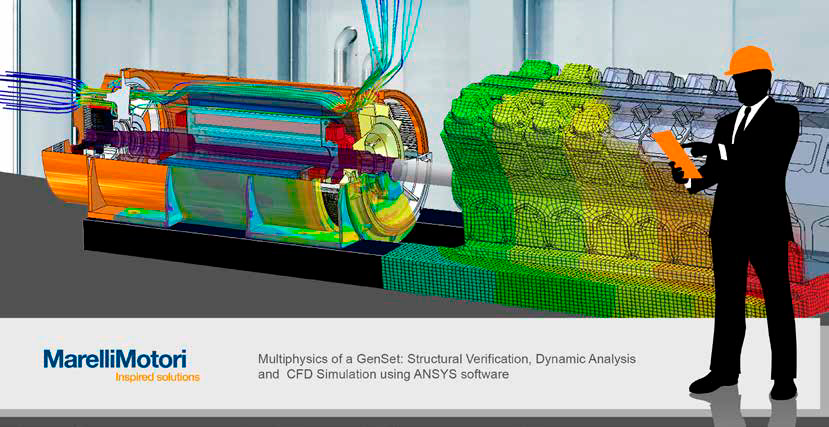

Improving efficiency while reducing cost is a very complex engineering challenge. Marelli Motori makes extensive use of CFD and FEM multiphysics simulation to do just that in the design of its electrical motors and generators.

ansys automotive cfd

CASE STUDY

Faber Spa, which has designed and manufactured ventilation hoods for the past 50 years, holds a key global position both in terms of production and technology. It has achieved this position through strategic investments in research and development.

ansys appliances consumer-goods cfd

CASE STUDY

The article describes a study on the behaviour of a vertical-axis washing machine's hydraulic balancer, which is a critical component that helps to balance the load during the spinning phase of the washing cycle. The study was conducted by SPM, a company that specializes in dynamic analysis, to confirm a hypothesis that the flexibility of the tub was causing the imbalance and to validate a proposed modification to stiffen the structure.

appliances particleworks recurdyn multibody cfd

CASE STUDY

The challenge was to find the optimal aerodynamic design while substantially reducing the costs associated with traditional CFD modeling.

aerospace cfd ansys

CASE STUDY

In this case study, LION Corporation uses Particleworks to simulate fluid flow to improve the design of a new cap spout for its new HARETA brand of laundry detergent.

particleworks cfd consumer-goods mechanics

CASE STUDY

This article describes how SAER ELETTROPOMPE used Ansys CFX to transform "standard" pumps into pumps to be used as turbines.

energy ansys cfd

CASE STUDY

This study discusses the complex and challenging problem of controlling vortex-induced vibrations (VIV).

cfd mechanics ansys rbf-morph

CASE STUDY

In this technical article, we demonstrate how to apply a one-way coupling technique using a combination of ParticleWorks and LS-DYNA to estimate tsunami damage to a vehicle.

automotive ls-dyna energy cfd particleworks environmental

CASE STUDY

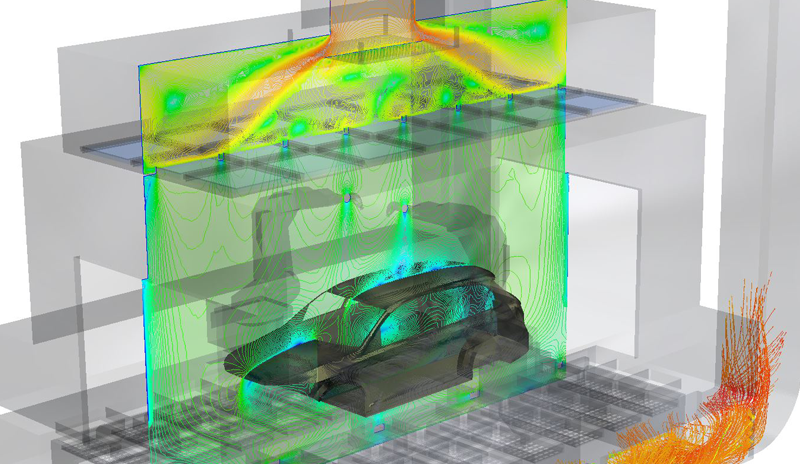

Overspray is a key problem in the paint application process. This phenomenon is caused by inefficiencies of the robots inside the spray booth and can best be solved by balancing the air flow properly in the paint application area.

automotive ansys cfd

CASE STUDY

Thermal management (TM) is a critical challenge in developing efficient, compact, and reliable electrified products in the automotive industry and beyond. TM encompasses strategies and technologies that maintain optimal operating temperatures for system components, ensuring safety and efficiency. This study explores TM in electrified products, focusing on the integration of hydraulic units, electric motors, and electronics, and the importance of system-level design from the pre-design phase.

automotive cfd

CASE STUDY

The Extremely Large Telescope (ELT) is a 40m-class optical and infrared telescope being built in Chile. The ELT has a complex geometry, with a rotating structure and a dome that must be protected from wind effects to ensure accurate observations. To study the wind flow within the dome, a computational fluid dynamics (CFD) model was created.

civil-engineering cfd ansys

CASE STUDY

This technical article presents a study to design a device that operates entirely on the principle of trapped vortices that intrinsically improve the mixing of hot combustion gases with fresh mixture, a characteristic that is essential both to diluted combustion and to Moderate or Intense Low-oxygen Dilution (MILD) combustion.

ansys cfd turbomachinery energy oil-gas

CASE STUDY

This project has been coordinated by the German Aerospace Center (DLR) and it is embedded in the MELiSSA framework of ESA research projects.

aerospace cfd ansys

CASE STUDY

Racing engines are continuously evolved and fine-tuned to allow them to achieve extraordinary levels of performance, albeit with great complexity. However, MotoGP regulations restrict engine development by constraining some of the main design parameters.

optimization modefrontier cfd ansys rail-transport

CASE STUDY

In this technical article, EnginSoft and Prometech explain how they executed a highly complex computational simulation on the fluid-structure interaction of the oil flow inside a reciprocating engine, on behalf of Honda R&D.

automotive cfd particleworks

CASE STUDY

This technical article presents the study of a radial piston hydraulic motor with an outside cam arrangement for Bosch Rexroth Mellansel AB.

turbomachinery cfd particleworks

CASE STUDY

This technical article describes how high-end numerical Computational Fluid Dynamics (CFD) simulations were applied to mimic the realistic operating conditions of a Ventricular Assist Device (VADs) and analyze its hemodynamics in order to identify potential areas for optimization of the device’s performance, safety and efficacy.

ansys cfd biomechanics

CASE STUDY

This work presents the CFD model of an axial piston pump and compares it to a validated 0D model. The main objective of this study was to analyze the flow field inside the pump, focusing on the aspects that involved the main inner volumes, such as the filling and emptying dynamics in the piston chambers and the flow field inside the ducts.

ansys cfd energy

CASE STUDY

In this article, Uteco describes how it applied Computational Fluid Dynamics (CFD) to assist the design and improvement of its printing machines.

cfd ansys mechanics

CASE STUDY

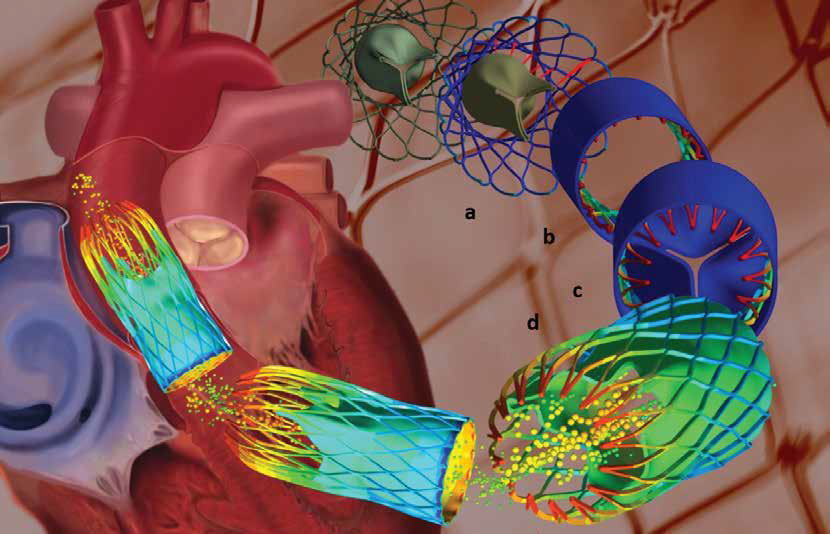

Since this cannot be accurately measured in an implanted stent, manufacturers decided to use Multiphysics to simulate the process to better understand the method and to calculate the forces operating on the implant in order to improve the stent design and the surgical procedure, as described in this article.

cfd biomechanics ansys

CASE STUDY

Rotary lobe pumps are the most reliable pumps in agriculture but, like all other technical equipment, they have to be optimized and constantly redesigned to continue competing in the market.

turbomachinery twinmesh

CASE STUDY

Gamma Meccanica’s R&D department is constantly researching new solutions to improve the overall performance of equipment, production capacity and reliability while developing environmentally sustainable processes and applications to benefit its customers.

cfd mechanics ansys

CASE STUDY

Further reduction of the heat loss compared to the best design of the NSGA-II first phase design optimization: a further 4% gained

cfd biomechanics ansys modefrontier optimization

CASE STUDY

This article describes how EnginSoft applied a Computational Fluid Dynamics (CFD) analysis, on behalf of Whirlpool EMEA, to simulate three different geometrical design modifications to the vacuum cleaner head to improve on a baseline performance that was modelled first.

appliances cfd ansys

CASE STUDY

This technical article describes how CFD analysis minimizes trial and error activities and costs and improves RFT – “right first time” – results.

consumer-goods cfd furniture ansys

CASE STUDY

Traditional naval architecture meets the CFD analysis with the aim to improve consolidated products reaching values in terms of performance never seen before.

ansys cfd marine