Ansys Additive Print

Ansys is a software suite of Ansys Inc.

Ansys is a software suite of Ansys Inc.

Ansys Additive Print eliminates the guesswork and hours of wasted time in metal additive manufacturing workflows. This easy-to-use stand-alone solution is useful for Additive machine operators and design engineers who need to build parts first-time-right.

Additive Print allows to:

Additive Print enables to predict:

Ansys Additive Print is included in Ansys Additive Suite and is also available as a stand-alone module.

Request a free demobrochure

Ottime potenzialità nella riprogettazione di parti di macchine e stampi per la produzione

Ansys Additive

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

A lot of steel structures such as cranes, heavy machinery and other equipment subjected to repetitive loading is highly likely to develop cracks or failures because of the fatigue damage. The cost of every hour of equipment downtime is usually very expensive, making it mandatory to perform residual life calculations or fatigue checks.

ansys energy

training courses

Artificial Intelligence applied to design, modeling and management of laboratory data, fundamental for project development, has clearly demonstrated significant and concrete advantages. These translate into both a reduction in calculation times and a clearer understanding of the phenomena detected by laboratory tests during the product design and development phases. The "Design and data analysis using AI" catalog offers a complete and advanced training path to develop fundamental skills in the field of design and data analysis, as well as in the creation of simplified numerical models using advanced Artificial Intelligence techniques.

training artificial-intelligence machine-learning dataanalytics

CASE STUDY

This technical article presents a study to design a device that operates entirely on the principle of trapped vortices that intrinsically improve the mixing of hot combustion gases with fresh mixture, a characteristic that is essential both to diluted combustion and to Moderate or Intense Low-oxygen Dilution (MILD) combustion.

ansys cfd turbomachinery energy oil-gas

CASE STUDY

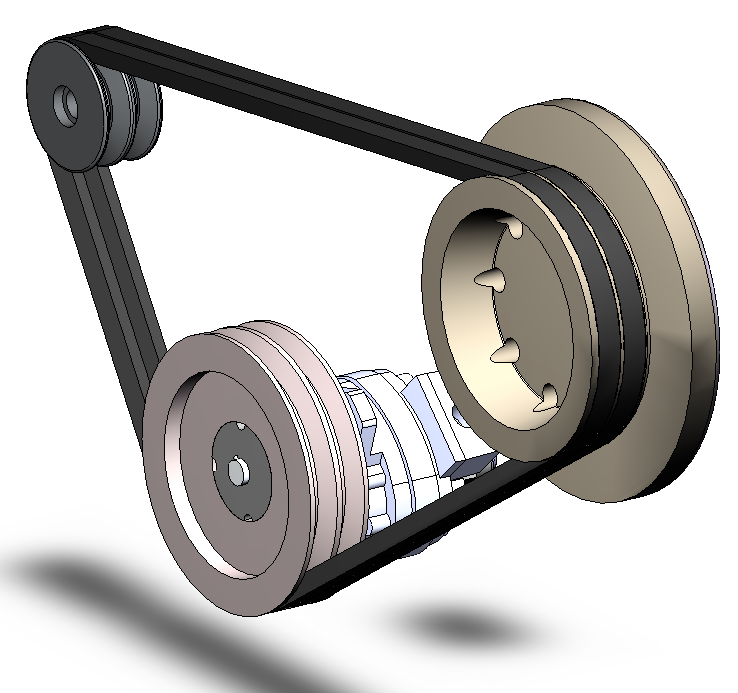

A virtual prototype of a belt must necessarily include the high flexibility of the belt itself, as well as a detailed description of the contacts. This is another scenario where RecurDyn provides better functionality than its competitors.

multibody mbd-ansys recurdyn

CASE STUDY

Stacker cranes handle pallet placement in the warehouse, moving longitudinally along the aisles between the warehouse shelves to deposit and retrieve loads. Stacker cranes are susceptible to earthquakes that can damage them and the racks around them.

mechanics civil-engineering