Energy

Recovery of Mechanical Energy from fluids to feed and Internet of Things (IoT) node that monitors diesel-engine exhaust gases.

The project proposes the development of a system to recover kinetic energy from easily accessible sources in order to make it immediately available for equipment in daily use (e.g. sensors for wearable devices, very low power actuators, low range wireless transmitters, etc.), whose need to be as energy independent as possible is propelling a rigorous search for appropriate technological solutions.

The proposed energy recovery system is based on an innovative technology composed of recyclable and environmentally friendly materials, which uses extremely flexible piezoelectric devices and very small dimensions to recover kinetic energy from gaseous fluids (e.g. wind, gases in pipes and air currents), but also from the movement of liquids (e.g. waves, sea and river currents), and which has virtually zero environmental and visual impact.

EnginSoft is the project coordinator and will conduct the FSI (fluid structure interaction) and system simulation activities.

ENGINSOFT SPA | IIT - ISTITUTO ITALIANO DI TECNOLOGIA (CENTER FOR CONVERGENT TECHNOLOGIES) | WEBELETTRONICA SRL

Funding Scheme: MISE Programma Operativo Nazionale (PON) “Ricerca e Innovazione 2014-2020” -European Regional Development Fund (ERDF) 2014-2020 EU Structural Funds

Some of our competences in research and technology transfer

Research project

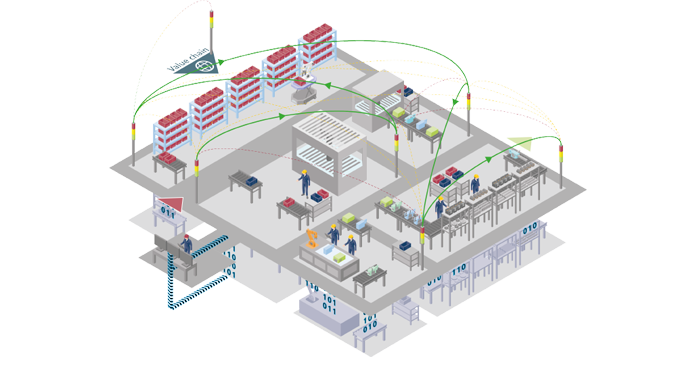

The overall objective of the RaRe2 project is to create a flexible and resilient Holistic Ecosystem Platform powered by the interactions of many European organizations interested in cooperating in the rapid reconfiguration of process chains through collaborative systems and adaptive workforce up-skilling.

Research project

The initiative is set to transform the European remanufacturing industry by addressing its current limitations and setting new standards for human-centric innovation. It aims to develop and demonstrate a novel remanufacturing paradigm which is inherently safe for humans, target-driven in regeneration and certification, flexible in handling post-use parts variability, and robust for replication in new circular business cases. To achieve these objectives, rEUman partners will develop cutting-edge remanufacturing approaches and integrate them into the value chains.