Smart Manufacturing

The development of highly efficient production systems able to minimize production costs and improve productivity and product quality is universally recognized as one of the central themes of Smart Manufacturing, particularly in the context of the Industry 4.0 vision. Highly efficient production is essential for the competitiveness of all companies wanting to achieve improved performance, and to differentiate themselves from low-cost countries through the production of high quality products, an aspect that is particularly significant for the Veneto manufacturing sector. Furthermore, systems with high application flexibility can maintain their efficiency even in the face of extreme variability in demand, while reducing waste (also for environmental sustainability) and the energy consumption resulting from inefficient manufacturing processes (energy efficiency). In this light, it is necessary to develop integrated methodologies, technologies and tools for maintenance, quality control, and production logistics.

The PreMANI project aims to demonstrate the applicability of these techniques across disparate application domains, characterized by very different needs, by leveraging methodological aspects of a general nature.

The project will develop techniques to predict the operating characteristics of machines and plants by combining quality analysis (of the product) with efficiency analysis (of the plants), within a context described as Predictive Manufacturing. The developed solutions pertain to the realm of Digital Manufacturing and include the creation of advanced tools for decision support, hardware components (dedicated sensor architectures, low-cost embedded systems for real-time use of complex prediction models), infrastructural components (cloud-based IT platforms), and algorithmic elements (with particular emphasis on the use of machine learning techniques).

The project is particularly challenging given the diversity of application areas. In fact, the industrial sectors in question represent paradigmatic examples of operating environments in which increasing intelligence ("smartness") is required of individual machines that must operate in interconnected environments (mechanical-textile, packaging, precision machining), and in complex and articulated processing systems (foundries, large-scale industrial production, food production systems).

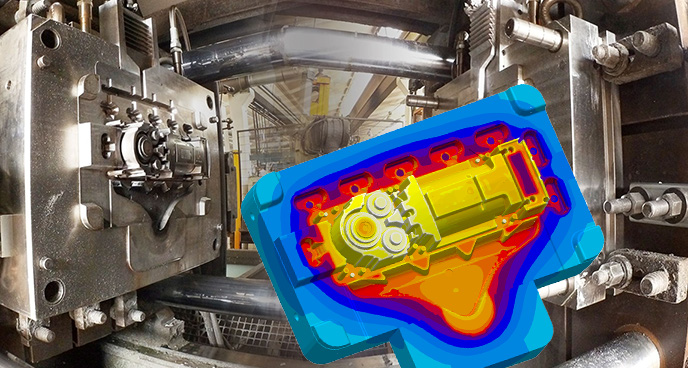

EnginSoft is providing “SmartProdActive”, an innovative tool to diagnose the quality, energy-consumption and costs of the production process in real-time. EnginSoft developed this application within the European FP7 project “MUSIC”, creating a digitalization application to control and predict vertical quality for foundries and injection moulding. During the PreMANI project, EnginSoft’s goal is to further develop and validate the "SmartProdActive" application in die casting, iron casting plants and machining, extending and generalizing it to become a transversal system to digitalize production, while testing its scalability and flexibility in other sectors.

CIELLE SRL, EDALAB SRL, ELECTROLUX ITALIA SPA, ENGINSOFT SPA, FONDERIA CORRÀ SPA, GALDI SRL, M3E ERL, M31 ITALIA SRL, RDS MOULDING TECHNOLOGY SPA, SIMNUMERICA SRL, SMIT SRL, SORDATO SRL, STATWOLF DATA SCIENCE SRL, T2I - TRASFERIMENTO TECNOLOGICO E INNOVAZIONE SCARL, UNIVERSITÀ DEGLI STUDI DI PADOVA, UNIVERSITÀ DEGLI STUDI DI VERONA, ZANARDI FONDERIE SPA.

Funding Scheme POR - Obiettivo "Incremento dell'attività di innovazione delle imprese" - Parte FESR fondo europeo di sviluppo regionale 2014 - 2020

“Progetto finanziato con il POR FESR 2014-2020 Regione del Veneto” - ASSE 1 “RICERCA, SVILUPPO TECNOLOGICO E INNOVAZIONE” AZIONE 1.1.4 “Sostegno alle attività collaborative di R&S per lo sviluppo di nuove tecnologie sostenibili, di nuovi prodotti e servizi”

Project co-funded by POR ERDF 2014-2020 Regione del Veneto" - AXIS 1 "RESEARCH, TECHNOLOGICAL DEVELOPMENT AND INNOVATION" ACTION 1.1.4 "Support for collaborative R&D activities for the development of new sustainable technologies, new products and services"

Importo finanziamento: € 2.999.858,64 / 64 / Grant Amount: € 2.999.858,64

36 months

November 2017 - October 2020

Improvenet, I.R.S. Srl

Nicola Gramegna

19

by Nicola Gramegna | EnginSoft

Andrea Salata | RDS Moulding Technology

Futurities - Summer 2022

The PreMANI project proved that digitalization in the foundry is an enabler for small and large companies. This article describes the design of a new sensorized mould for the production of Siemens gear motor housings and the implementation of an intelligent monitoring system supported by a predictive quality model created through instructive sampling.

Currently ongoing, the project prototype has been recently birthed, having human placenta reproduced in a laboratory.

Read the article

Some of our competences in research and technology transfer

Research project

Development of a novel “manufacturing system-level quality and productivity optimizer tool” enabling the evaluation of the system level impacts of the defect avoidance policies that can be adopted within single processes.

Research project

The SERENA project aims to develop a prototype propulsion system for a General Aviation-category aircraft based on hybrid power technologies (hydrogen-fueled cells, batteries, and super-capacitors).