OScaR

Optical SCAn-and-Repair solution for machine tools

Manufacturing

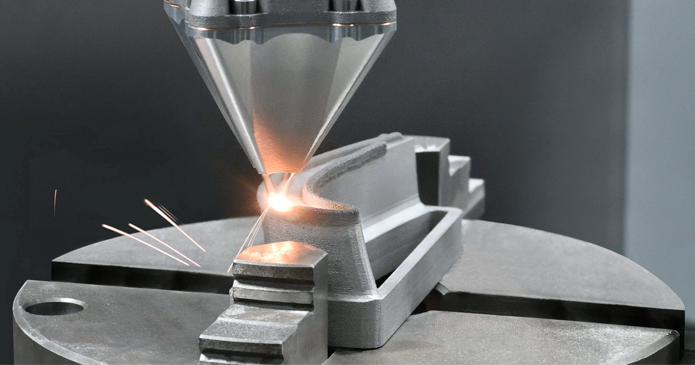

The final goal of the project is to define a technology solution to repair metal components. End users require an automated or semi-automated solution for mounting a part of partially unknown shape into a machine, measuring the relevant part of its surface in 3D and automatically generating a repair program to restore it to the desired shape. The resulting piece also needs to be analyzed automatically for inline quality control. Moreover, since the repair process does not allow for error, a simulation tool for pre-assessing the achievable results is mandatory, especially for additive manufacturing processes for repairs.

In many modern manufacturing applications, in-situ reconstruction of part geometry is a relevant aspect of the production pipeline. For example, damaged parts can often be repaired/re-manufactured to extend their lifecycle, but repairing a damaged part means that the chosen manufacturing technology must be applied to a surface of unknown shape. This is also relevant for parts that must be manufactured by moving through multiple machines, especially when pre-manufactured externally. End users in many fields would benefit from the ability to easily modify multi-process parts and to repair customers’ damaged parts, but lack a consolidated technology with which to easily (1) work on existing parts with far-from-nominal geometry, and (2) generate an AM-DED repair tool path for a damaged segment. Additionally, quality control of the new part must be completed outside the machine, requiring supplementary production time.

Overall impact for the manufacture and repair industries is to enable:

OScaR enables repair of complex metal parts for high quality applications by integrating an AM-DED (Directed Energy Deposition) machine, in-situ 3D scanning, DED simulation and toolpath generation to achieve the next level of flexible manufacturing.

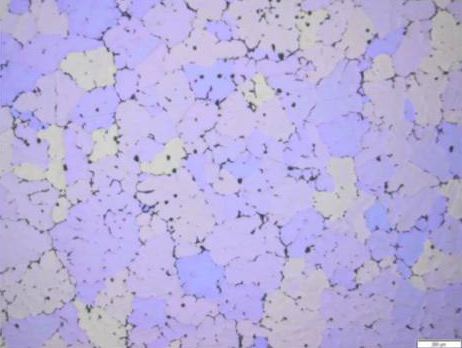

EnginSoft’s role is to set up a suitable model, based on Ansys, to simulate the repair process , to virtually replicate the repair operations performed by Directed Energy Deposition, and to display the repair process on the reference part. The Ansys DED simulation module imports a scanned baseline geometry and an externally generated G-Code. The main materials and process configurations relevant to the use cases are the inputs for the simulation parameters. The final simulation of the deposition process and of thermo-mechanical deformation was developed and tested on the two main use cases which included the validation of the results compared to real measurements.

PRIMA ADDITIVE SRL | SUPSI - Scuola Universitaria Professionale della Svizzera Italiana | INSPIRE AG | AIDIMME | POZZO SPA | ENGINSOFT SPA

EIT Manufacturing Call for Proposals 2022 “Flexible production systems for competitive manufacturing “

12 months

January 2022 – December 2022

PRIMA ADDITIVE

Daniele Calsolaro

6

by Daniele Calsolaro, Livio Airaudi | EnginSoft

Futurities - Autumn 2023

OSCAR was a collaborative undertaking to define a technological solution for repairing metal components using Directed Energy Deposition (DED) Additive Manufacturing (AM).

The successful implementation of this method has been tested with two case studies, on laboratory and industrial applications.

Read the article

Some of our competences in research and technology transfer

Research project

The GAP Project’s innovativeness lies in the development of innovative metallic materials with multi-sector application potential, increased by experimentation with new specific technologies (e.g. the use of ceramic cores for die-casting, surface treatments, and joining techniques).

Research project

Il progetto “TEMART - Tecnologie e materiali per la manifattura artistica, i Beni Culturali, l’arredo, il decoro architettonico e urbano e il design del futuro” ha l’obiettivo di migliorare i prodotti dei settori citati (funzionalità ed estetica) mettendo a loro disposizione le diverse tecnologie che sono presenti nella RIR M3NET.

Research project

The project aims to combine performance optimization of company with a strong investment in human capital, creating a highly digitalized business environment to make the company more competitive, efficient and ready to face future challenges: this will be achieved thanks to a more competent and prepared team, through the introduction and use of innovative applications and systems, aimed at simplifying daily processes and operations.