HYSSE

Hydroponic SubSystem Engineering

Space - Bio system Engineering

Develop an innovative design of a sealed gully and hydroponic system for space applications of food production with regenerative systems: space stations, lunar base and Mars exploration. The project will develop, manufacture and test a ground based pilot test facility. Full life cycle of three crops will be carried out: potato, soybean and durum wheat.

The activity will first develop concepts of closed water tight systems, for the gully and the hydroponic. NFT (Nutrient Film Technique), MD (Mist Dispenser, DWC (Deep Water Culture) concepts will be evaluated as well as mixed/hybrid systems. A predesigned system will address components' cost and control issues for space operations.

Fundamental tests and procedures will then be carried out for germination, disinfection, contamination, nutrient feed and nutrient uptake on the single crops, together with the first CFD simulations of the gully multiphase component. The hydroponic fluid system will then be designed with flow balancing, culture system control, thermal control with monitor and actuation strategy. Finally a breadboard will be manufactured in order to carry out all the functional and life tests.

A first set of functional tests will investigate the robustness of the control system, failure scenarios, nutrient feeding and control and a user manual will be written. In a second phase full life tests for the growth of potato, soybean and durum wheat will be carried out. These test will allow to monitor crop growth , nutrient uptake, leaf gas exchange in the new engineered hydroponic. Finally recommendations for the design of a future PCU (Plant Control Unit) will be delivered.

Space food production with regenerative systems is a long term project addressed by ESA (European Space Agency) with the MELiSSA programme (Micro Ecological Life Support System Alternative). A completely sealed environment between the root zone and the leaf zone has never been tested, thus mass balance and/or contamination between the two environments cannot be controlled. HYSSE addresses the development of a sealed system for the roots so that the rhyzosphere environment can be characterized and studied in standalone mode.

EnginSoft has been in the past present as a partner in other ESA projects for life support systems. The engineering background of the company has leveraged a higher level involvement in the continuation of these projects and ES role is now of coordinator with direct involvement in design issue with ESTEC (Europena Space Technological Center) scientists. EnginSoft is coordinating bio, chemical scientists in an international environment for the success of this project.

EnginSoft SpA | NTNU Norvegian University of Science and Technology | Universiteit GENT | ULB Université Libre de Bruxelles | Polytechnique Montréal | University of Guelph | Sherpa Engineering

Funding Scheme MELiSSA Food Characterization Phase 2: PCU Sub-system engineering | Call identifier 3-13610/12/NL/JC

Some of our competences in research and technology transfer

Research project

Il progetto supporta alcune aziende della rete SINFONET nell'utilizzo di servizi specialistici, di assistenza, orientamento, affiancamento, informazione e promozione dell’export, per promuovere non solo le proprie specificità ma anche l’intero complesso della filiera fonderia.

Research project

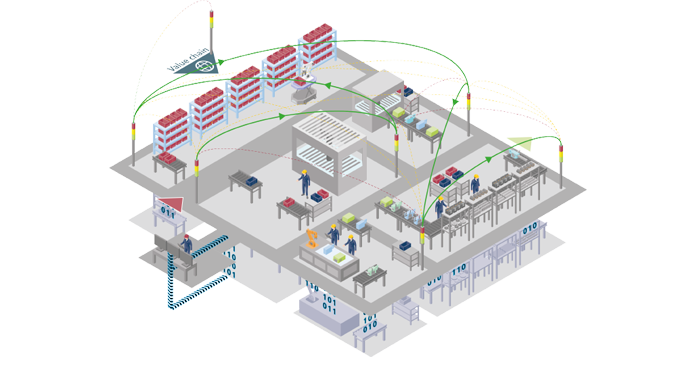

The overall objective of the RaRe2 project is to create a flexible and resilient Holistic Ecosystem Platform powered by the interactions of many European organizations interested in cooperating in the rapid reconfiguration of process chains through collaborative systems and adaptive workforce up-skilling.