Space

The ultimate goal of the project is to “open” a new operating area in Space, namely that of Very Low Earth Orbits (VLEO), or orbits between 160 and 250km in altitude.

The operating area of Very Low Earth Orbits (VLEO), or orbits between 160 and 250km, is currently precluded to both aeronautics and space systems, and its operational availability would pave the way for a new phase of innovation in Earth observation services. Achieving this goal requires intensive research and the achievement of numerous partial objectives, which are well-suited to the main thrusts of Space development.

The first result of the project is to create a RAM-EP system capable of fully compensating for aerodynamic drag, collecting, ionizing and accelerating a flow representative of the VLEO conditions.

Another result is to create a manifold with a geometry compatible with the results obtained from the mission analysis activities and that is able to passively compress the incoming flow. Moreover, the research will evaluate the feasibility of a vehicle that supports the RAM-EP system, satisfying the interface requirements (required power, mass and dimensions). This objective is achieved through the application, at the system and subsystem levels, of systems engineering processes and methodologies.

The final goal is to study a mission configuration with optical and SAR payloads that exploits the great advantage of VLEO orbits.

EnginSoft is involved in developing a Graphical User Interface (GUI) for a numerical code developed by the CNR (the Italian Research Council) which simulates hall-effect thrusters.

EnginSoft is also involved in the study and characterization of the stresses at VLEO orbits and will support the partner SITAEL in structural (from static to thermoelastic), thermal (radiative and orbital thermal, transient LEOP) and electrical analysis.

DTA - DISTRETTO TECNOLOGICO AEROSPAZIALE, BLACKSHAPE SPA, CNR - CONSIGLIO NAZIONALE DELLE RICERCHE, ENEA - AGENZIA NAZIONALE PER LE NUOVE TECNOLOGIE, L’ENERGIA E LO SVILUPPO ECONOMICO SOSTENIBILE, ENGINSOFT SPA, GAP, IMT, PLANETEK SRL, POLITECNICO DI BARI, SITAEL SPA, UNIVERSITÀ DEGLI STUDI DI BARI “ALDO MORO”, UNIVERSITÀ DEL SALENTO

Funding Scheme MIUR Programma Operativo Nazionale (PON) “Ricerca e Innovazione 2014-2020” | Call identifier Avviso MIUR n. 1735 del 13/07/2017

30 months

October 2018 - March 2021

Distretto Tecnologico Aerospaziale (DTA) scarl

Mariarita De Rinaldis

12

Some of our competences in research and technology transfer

Research project

L’attività svolta, nell’ambito del progetto CUP B98I24002620009, si contraddistingue per due servizi volti a migliorare competenze, metodi e strumenti applicati al Process Engineering e Sistemi Informativi per il Knowledge Management (KM) e GoToMarket (GTM).

Research project

The PreMANI project aims to demonstrate the applicability of these techniques across disparate application domains, characterized by very different needs, by leveraging methodological aspects of a general nature.

Research project

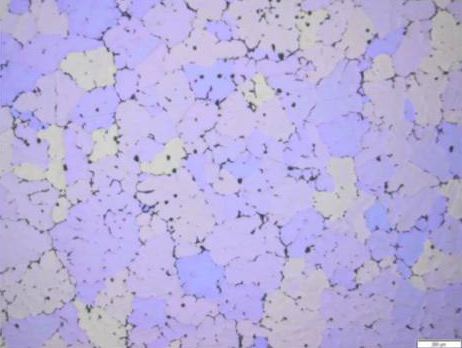

L’innovatività del progetto GAP consiste nello sviluppo di materiali metallici innovativi, con potenzialità applicative multi-settoriali, incrementate dalla sperimentazione di nuove tecnologie specifiche (utilizzo di anime ceramiche per la pressocolata, trattamenti superficiali, metodologie di giunzione).