LIFE SUPPORT SYSTEMS in the Space Industry

Author: Erik Mazzoleni, Marco Gatti | October 2025 | Reading time: 7 minutes

Life Support Systems are the backbone of human space exploration. They provide the essential conditions that allow astronauts to survive and work in the harsh environment of space, where there is no breathable air, no drinkable water, and extreme variations in temperature and radiation. At their core, life support systems maintain a stable and safe habitat by supplying oxygen, removing carbon dioxide, regulating pressure and humidity, recycling water, and managing waste.

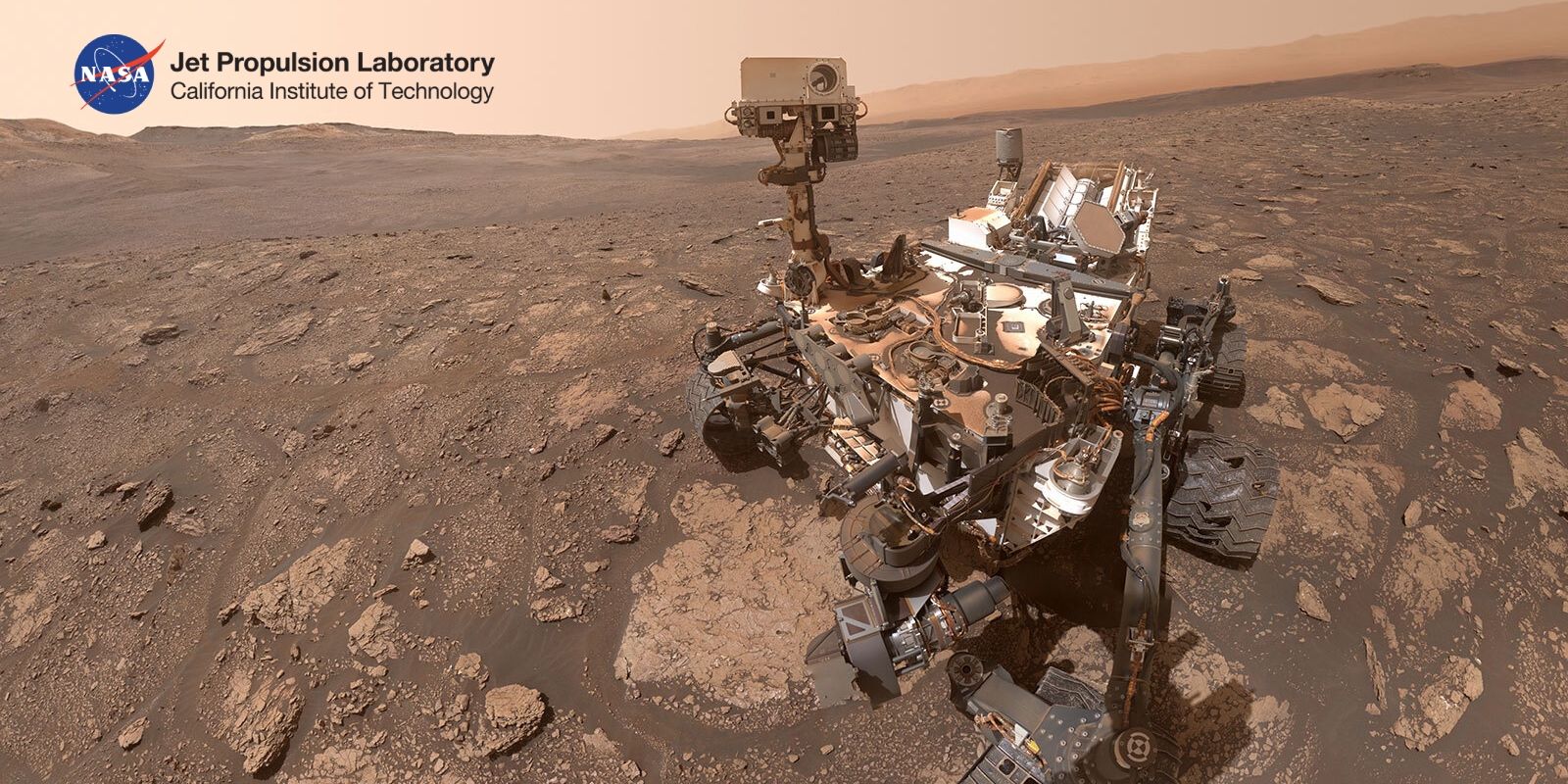

As missions extend beyond low Earth orbit—towards the Moon, Mars, and possibly beyond—the design of life support systems becomes even more critical. Unlike the International Space Station (ISS), where regular resupply from Earth is possible, long-duration missions will require systems that are highly efficient, reliable, and largely self-sustaining. This has led to growing interest in regenerative life support technologies, which recycle air, water, and other resources, and in bioregenerative systems, which use plants or microorganisms to close the loop further.

In short, life support systems are not just technical equipment; they are ecosystems that must balance human needs with the extreme challenges of space. Their development is central to making long-term human presence beyond Earth both possible and sustainable.

Currently, a potential mission to Mars envisages supporting a crew of six astronauts, who will need to breathe, eat, and drink off-Earth for nearly two years. This will either require them to carry stock of huge quantities of oxygen, water, and food, or to use a circular recycling system to produce the oxygen, water, and food they will need during the mission.

The MELiSSA (Micro-Ecological Life Support System Alternative) program is the European Space Agency’s leading effort to develop a closed-loop, bioregenerative life support system for long-duration human space missions (www.melissafoundation.org). Active for more than 30 years, it brings together research centers, universities, and industries across Europe to recycle air, water, and waste while producing food using microorganisms and higher plants. Along the way, the program has generated extensive know-how, including applications of Spirulina as a resource for oxygen and protein production, and has advanced technologies now being validated in demonstrators like the MELiSSA Pilot Plant (MPP) in Barcelona, Spain, and the PACMAN Plant Characterization Unit (PCU) in Naples, Italy.

For the past 20 years, EnginSoft has been collaborating with ESA on the MELiSSA program, actively working on life support systems for space environments as a member of the MELiSSA Consortium and as a project coordinator, with a particular focus on the food production compartment. In this role, the company first contributed to the air management system of the compartment, enabling the optimized evapotranspiration of plants during growth. EnginSoft was also involved in investigating closed-loop recycling systems and related technologies for Ground test facilities. For example in the EDEN-ISS project (eden-iss.net), EnginSoft was responsible for the design and simulation of the air management system for a greenhouse in Antarctica, demonstrating that it was possible to produce different vegetables in a hostile environment (Figure 1).

Fig. 1: EDEN ISS Greenhouse (left) and Air management system (right). Courtesy of DLR

Recognizing this expertise, ESA entrusted EnginSoft with one of the program’s major undertakings: the design and development of the Plant Characterization Unit (PCU), a state-of-the-art ground-based research facility located at the University of Naples. The PCU enables high-quality data collection for modelling purposes and allows the MELiSSA community to perform advanced scientific experimentation on crops.

The PCU, shown in Figure 2, consists of a growth chamber, specifically designed for plant cultivation and equipped with sophisticated sensors and environmental control systems. Its main objectives are to quantify oxygen production, CO2 consumption, and water renewal, while also characterizing the effects of parameters such as temperature, light intensity, and nutritional composition on the plants behavior to support the development of an artificial ecosystem. Developing the PCU required addressing several demanding engineering challenges, with special attention to minimizing the leakage rate. Indeed, the level achieved is very low compared to typical industry standards. An advanced nutrient delivery system was also implemented, allowing precise control of solution composition and pH through the dosing of acid, base and eight stock solutions for a total of ten side tanks, each equipped with a peristaltic pump and scale for volume calculation. Moreover, the control system regulates the growth chamber environment - temperature, relative humidity, and airflow - to ensure optimal conditions for scientific experimentation. Life-tests performed in the PCU have shown the capability of the system to produce oxygen, absorb carbon dioxide and recycle water. The technological ability to generate oxygen through photosynthesis (Figure 3), will allow future astronauts to have a spare supply of oxygen, thereby reducing the need to carry storage tanks for long-term space missions, whereas the water produced by the lettuce can be recycled and used as drinking water for the astronauts.

Fig. 2: Plant Characterization Unit (PCU)

Fig. 3: Oxygen and Carbon dioxide measurements

With over 40 years of experience in modeling and simulation, EnginSoft entered the space sector through the development of the PCU within the MELiSSA program. This milestone led ESA to entrust the company with additional responsibilities, extending its role to the modeling and simulation of bio-regenerative life support systems. In this context, EnginSoft applied its core expertise to integrate process simulation, control strategies, and system-level evaluation into a unified approach for managing complex ecosystems (Figure 4).

Building on these achievements, the company has demonstrated its ability to deliver comprehensive solutions in the space sector covering:

- Design of gas and liquid management systems

- Simulation of single technologies or entire plants to virtually validate their performance

- Detail Engineering, Procurement and Assembly of the selected industrial solution

Leveraging this know-how, EnginSoft will continue to contribute to the development of regenerative life support technologies essential for the success of future long-duration human missions in space.

Fig. 4: Hierarchical control structure for a life support system

Recent Publications:

www.frontiersin.org/journals/astronomy-and-space-sciences/articles/10.3389/fspas.2022.820752/full

Newsroom

EnginSoft's blog offers news and valuable tips to overcome engineering challenges with a systemic and global vision

LIFE SUPPORT SYSTEMS in the Space Industry

aerospace cfd

What lies in the future for simulation? The Red Planet may have an influence…

research innovation aerospace

Health: Combining engineering and medicine for outstanding results

research innovation health

The potential for AI in industry and among SMEs – busting the myths

research innovation simulation

How to stay operational in a virtual world

optimization

The Value of Design-to-Cost

optimization

Simulating the multiphysics of a residual current device

electronics cetol

Thermal Optimization of oil-cooled e-Drives

particleworks