Abstract

The present work investigates the Warm Hydro Forming (WHF) process of an AA6xxx series alloy (AA6061-T6) using a numerical-experimental approach. As concerns the experimental activity, tensile and formability tests in warm condition were carried out to identify the mechanical properties: flow stress curves,

Forming Limit Curves (FLCs) and anisotropy values according to temperature and orientation respect to the rolling direction were obtained. In addition WHF tests were carried out using hydroforming facilities of the laboratory of Advanced Forming and Manufacturing (http://afmlab.poliba.it); the following process parameters were investigated: maximum oil pressure (pmax), Blank Holder Force (BHFmin and BHFmax) and working temperature.

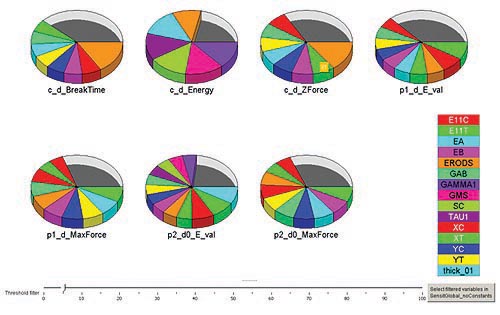

As concerns the numerical activity, Finite Elements simulations were focused on the best modeling of the WHF process: models were tuned in order to fit experimental results; in particular different values of the coefficient of friction (COF) and various yield criteria were assumed for fitting experimental data in terms of thickness reduction on the formed component. The Forming Limit Curves (FLCs) adoption, since determining the sheet formability, allowed to identify the critical areas (possible cracking or wrinkling). The post-processing was made by LS-PrePost.

Read the article