Franco Tosi Meccanica

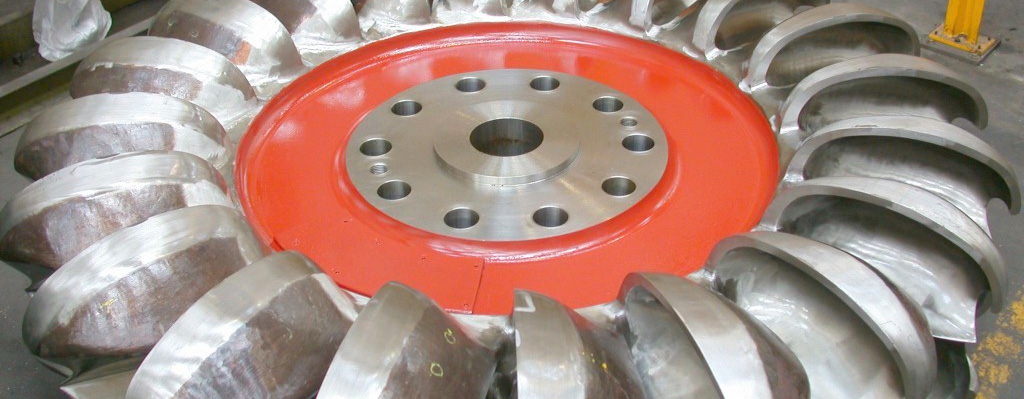

Pelton Turbine

Abstract

Hydropower is no doubt a major source of green power generation. Pelton turbines are widely used in hydropower generation because they are the most efficient type of water turbine available today.

Franco Tosi - a leader in the production of hydraulic and power steam turbines whose products are installed in 40 countries around the world - engaged EnginSoft's services to assist in the performance evaluation that needed to be done to upgrade an existing hydropower plant. The study was specific to a Pelton turbine that needed to be upgraded.

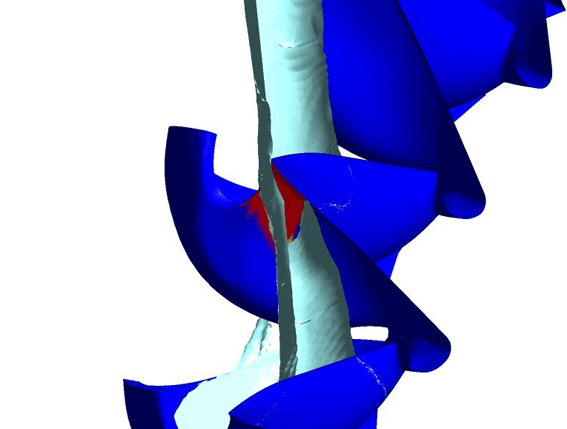

EnginSoft developed a Computational Fluid Dynamic (CFD) analysis methodology for the project.

This was an essential step in acquiring sufficient data to assist in the design that was ultimately used to upgrade the turbine in this power plant. The analysis methodology was applied to an existing machine in order to compute the actual turbine efficiency.