Strategy to optimize the independent suspension system of an off-highway, agricultural tractor

Futurities Year 19 n°4

By Federico Bavaresco, Lorenzo Bellorini – DANA

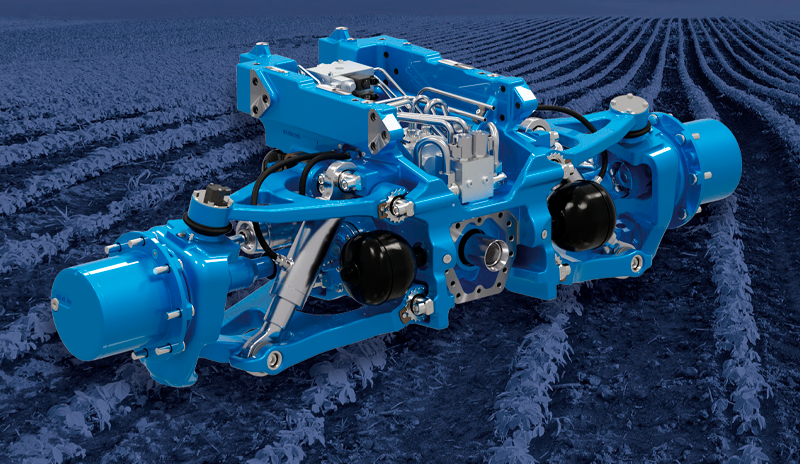

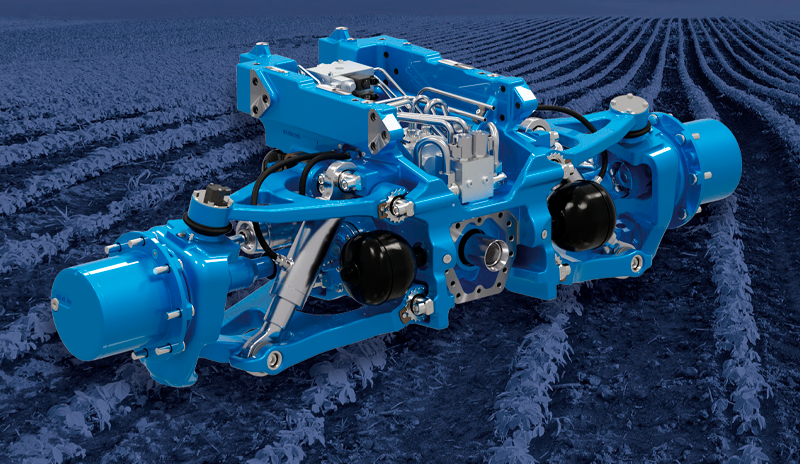

This article provides a more detailed discussion of the case study on the design optimization of the independent suspension axle of an off-highway vehicle (OHV) that was published in the summer edition of EnginSoft’s Newsletter last year.

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost.

This approach ensures that the best solution is always selected.

CASE STUDY

Optimization tools, and specifically response surface methods (RSM), can be adapted very well in the design process to provide information around the design of a compressor stage. This article will cover two of the possible optimization uses: the search of optimum performance and data generation.

modefrontier optimization mechanics

CASE STUDY

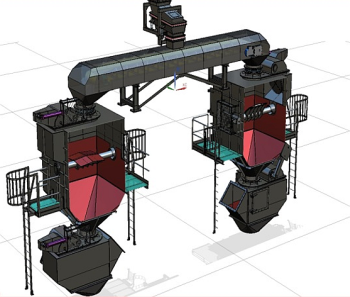

In the lime industry, the process engineers of Cimprogretti advise on process safety, analyse and interpret laboratory and plant data and provide specialised support to ensure the technical integrity of equipment and plants.

mechanics rocky