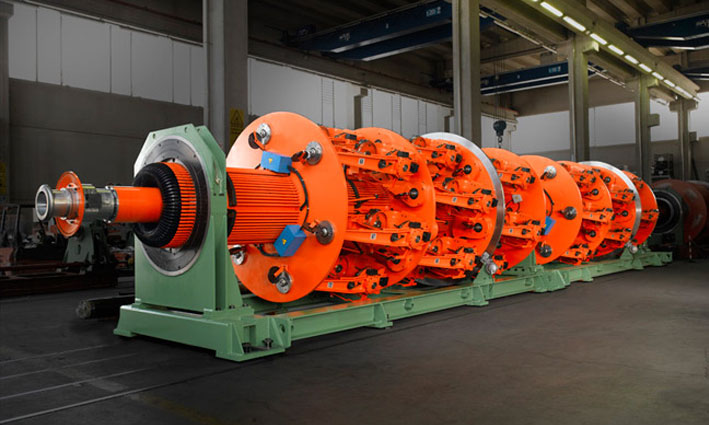

Stranding Machine

Stranding and closing planetary machines are huge pieces of equipment designed to twist multiple heavy spools of strand at noticeable speed, to manufacture large section steel ropes. The model was developed to: identify the worst operating conditions; choose the right electric motors; verify the braking system; and obtain the sizing loads for all the different parts of the machine.

The machine’s final user will be able to manufacture different types of rope by combining different strands in different ways. This means that the machine can be loaded with spools of different size, at different positions on the main rotor, with different levels of imbalance, and with different twisting speeds. The problem was approached through a Design of Experiments which analyzed 64 different load cases to identify the worst operating conditions. The collaboration provided reliable results in less time, and helped preserveMARIO FRIGERIO’s unparalleled level of quality.