A collaborative project between Nissan Technical Centre Europe, RBF Morph, and the University of Rome “Tor Vergata” showcases how multi-physics optimization is revolutionizing automotive wheel design, particularly for electric vehicles (EVs). By integrating styling, structural analysis, and aerodynamics within a unified workflow enabled by advanced mesh morphing technology (rbfCAE), designers can optimize wheels for lightweight, strength, and aerodynamic efficiency without compromising aesthetics.

The approach uses finite element analysis (FEA) for structural integrity and computational fluid dynamics (CFD) for aerodynamic performance, combined with two optimization methods: parametric morphing (user-controlled shape adjustments) and biologically inspired growth morphing (adaptive shape changes based on stress distribution). Both methods reduced wheel mass and improved performance metrics, with only slight aerodynamic trade-offs.

This digital, multi-physics platform fosters real-time collaboration between designers and engineers, accelerating development while ensuring robust, visually appealing wheel designs that meet the demands of modern EVs. The work also points to future integration of AI and reduced order models for even faster, smarter design cycles.

Read the article

CASE STUDY

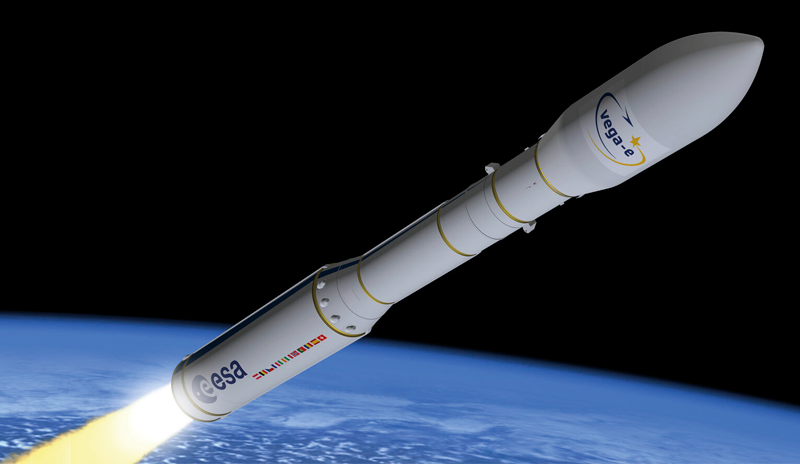

This article is based on a collaboration between RBF Morph and AVIO to configure a numerical optimization procedure to improve the Vega E M10 engine’s performance by optimizing the methane circuit of the injector head.

aerospace rbf-morph ansys meshing

CASE STUDY

This article combines the use of the finite element method with a Design Thinking approach to reconstruct a road traffic accident for an traffic accident insurance report in order to analyse the outcome of the accident, compare the respective property damage, and the physical injuries to pedestrians or passengers in order to limit the quantity of large claims compensation for the insurance company, while ensuring the fairness of the compensation for the customer to foster greater trust and credibility in the insurance provider.

automotive ls-dyna