The article focuses on the difference in fatigue behaviour between rubber and metal materials. While metal fatigue is often described by a simple rule: increasing mean strain is detrimental to fatigue life, rubber fatigue is more complex and depends on the material's ability to strain crystallize.

Rubber fatigue is influenced by the material's structure, which is composed of long chain molecules that can experience large, elastic/reversible straining. This structure allows for strain-induced crystallization, which can increase fatigue life. However, for amorphous rubbers, increasing mean strain reduces fatigue life, similar to metal fatigue.

The text also introduces the concept of critical plane analysis, which is essential for accurately predicting the effects of strain crystallization in rubber. This analysis involves computing fatigue life for many potential crack orientations and identifying the orientation that produces the shortest life. The Haigh diagram, commonly used for metal fatigue analysis, is also used for rubber fatigue analysis. However, the contours of the Haigh diagram for rubber can be quite different from those of metal, and the critical plane orientation can vary depending on the strain amplitude and mean strain.

The text concludes that while tensile mean stresses are always detrimental in metals, in rubber they may be either beneficial or harmful depending on whether the rubber can strain crystallize. The beneficial effect of mean stresses in rubber can be quite strong, and critical plane analysis is essential for accurately predicting the effects of strain crystallization in rubber.

Read the articlesoftware

Endurica provides solutions that put you in control of durability issues of elastomers components early in the development cycle. The Endurica solutions help our clients understand and manage the effects on fatigue life of nonlinear material behavior, component geometry, and complex duty cycles. Endurica has served leading companies in the automotive, medical device, offshore, and consumer products.

automotive endurica

CASE STUDY

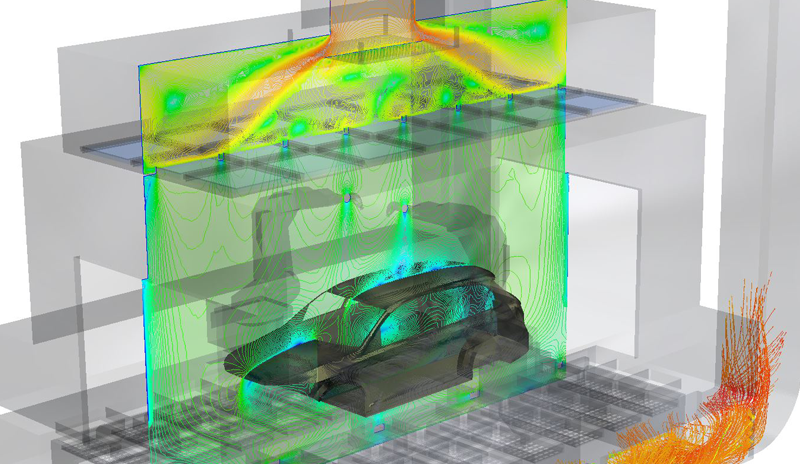

Overspray is a key problem in the paint application process. This phenomenon is caused by inefficiencies of the robots inside the spray booth and can best be solved by balancing the air flow properly in the paint application area.

automotive ansys cfd