Abstract

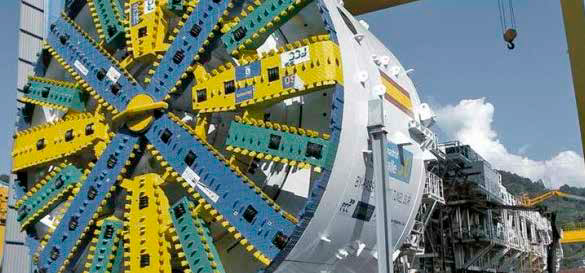

This technical article presents the study of a radial piston hydraulic motor with an outside cam arrangement for Bosch Rexroth Mellansel AB. Bosch Rexroth Mellansel provides complete hydraulic drive systems for heavy duty applications in different industries. Drive system performance, lower environmental impact and increased reliability are all high desirable characteristics for its customers.

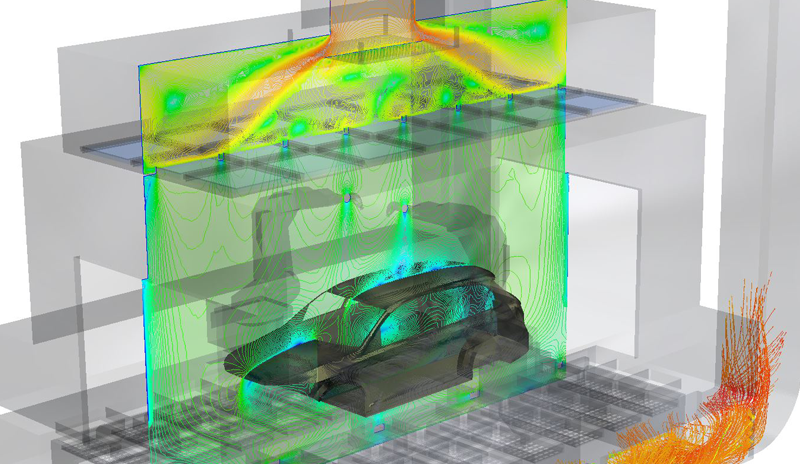

Torque and losses prediction, the calculation of oil residence time and understanding the flow path are important factors in achieving these characteristics. However, traditional fluid-dynamic modelling techniques are practically unfeasible due to the geometrical complexity of these systems. Here EnginSoft demonstrate how the mesh-less CFD methodology called Moving Particle Simulation could simulate the oil flow inside the entire radial piston engine to allow Bosch Rexroth to save time and money in engine development, while also better understanding the fluid dynamics inside the system.

Read the article