In this case study, LION Corporation uses Particleworks to simulate fluid flow to improve the design of a new cap spout for its new HARETA brand of laundry detergent. The HARETA liquid laundry detergent contains a polymer to increase its viscosity. It has a non-Newtonian viscosity meaning that the liquid tends to be less viscous during the pouring process. Instead of using its traditional design method of creating 100 product prototypes using 3D printers, the design engineers, with Promotech’s cooperation, created a simulation of the new bottle cap spout design and compared it to a conventional product to improve the pouring and measuring performance of a dose of laundry detergent.

The simulation enabled the engineers to calculate the velocity gradient and observe its effect on the whole flow-down phenomenon.

Read the articlesoftware

Particleworks is an advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method.

particleworks

CASE STUDY

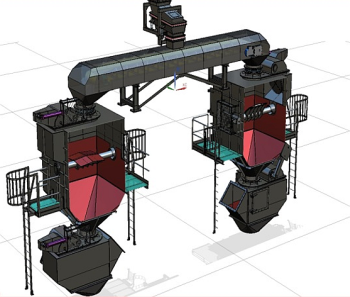

In the lime industry, the process engineers of Cimprogretti advise on process safety, analyse and interpret laboratory and plant data and provide specialised support to ensure the technical integrity of equipment and plants.

mechanics rocky