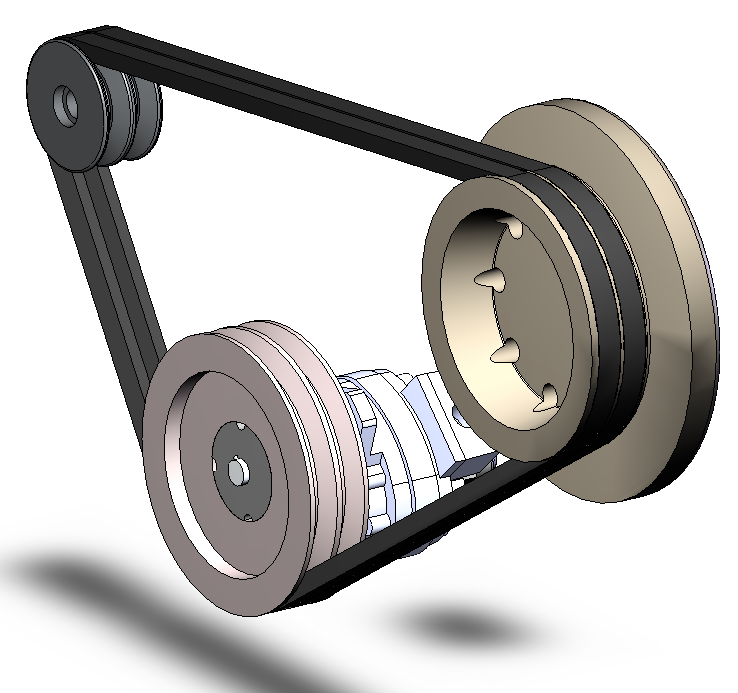

Flexible Belts

The flat belt is a simple system of power transmission that can deliver high power at high speeds. Flat belts are almost no longer used to transmit power, but they have not disappeared from industry. One still finds flat belts / tapes in machines that handle paper sheets, envelopes, and magazines. In these applications, they apply friction force to transfer items, instead of transferring power, from pulley to pulley. As flat belts tend to climb towards the higher side of the pulley, pulleys are made with a slightly convex or "crowned" surface. This creates a self-centering behavior during the belt’s operation. More generally, the dynamics of the belt are influenced by both the shape and the misalignments of the pulleys. Their behavior depends on the structural flexibility combined with the friction forces at the belt-pulley surface.

A virtual prototype of a belt must necessarily include the high flexibility of the belt itself, as well as a detailed description of the contacts. This is another scenario where RecurDyn provides better functionality than its competitors. In order to obtain a reliable belt model, both the Full Flex technology and Geo-Contact technology are necessary. The stress on the belt depends on both the local curvature and the longitudinal tension. The curvature introduces a bending stress whose amplitude depends on the difference between the local curvature and the curvature of the belt before being mounted. Flexible belts in RecurDyn are true Finite Element (FE) models, therefore, it is possible to extract the stresses (and the strains) from all over the structure, while taking into account all of the afore-mentioned effects.

Along its path, the belt may encounter third objects which actually perturb its dynamics. Very often, especially during high-speed transmissions, the belt preload is governed by a tensioner, a further pulley that applies a transversal force to the belt. The way that such a force is generated and transferred to the belt is important for the efficient functioning of the transmission. Very often, this tensioner pulley is supported by hydraulic components or preloaded non-linear springs, or a combination of these. RecurDyn allows the user to implement any kind of tensioner, from the simplest spring to the most sophisticated hydraulic type.