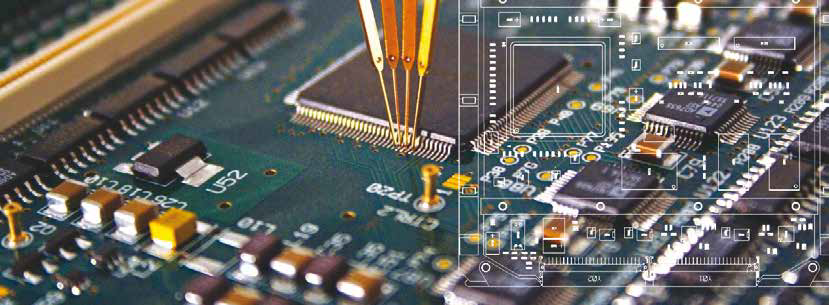

This technical article presents a simulation process to analyze fatigue in electronic parts, particularly in solder joints, on printed circuit boards (PCBs).

There are three core technologies in the process:

By applying a single frequency response analysis to the FE model of an electronic component containing the substitute FE models, and conducting static analyses of all the solder-joint sub-models, the vibrational solder-joint fatigue can be efficiently calculated in FEMFAT spectral, where the section forces in the pins of the electronic devices are mapped onto the sub-models and scaled by a power spectral density to calculate the damage in all solder joints.

Read the article

CASE STUDY

Simulation is nowadays strongly connected to new product development in most high-technology industries.

ansys electronics