Abstract

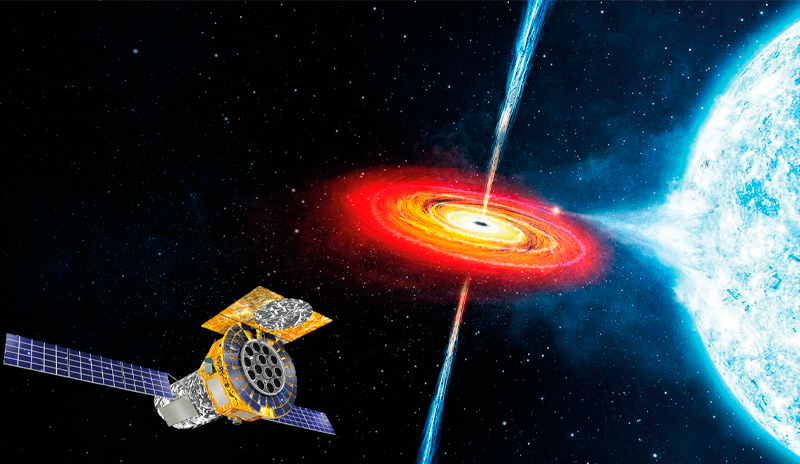

A major project of the Chinese Academy of Sciences (CAS) and the China National Space Administration (CNSA), the eXTP (enhanced X-ray Timing and Polarimetry) mission is currently conducting a phase B study and proposal for launch in 2027. The eXTP scientific payload includes a suite of instruments that offer simultaneous wide band X-ray timing and unprecedented polarimetry sensitivity. A large European consortium is contributing to the eXTP study and will provide key hardware elements, including the Large Area Detector (LAD) consisting of 40 modules with a total effective area of 3.2m2 at 8.0keV.

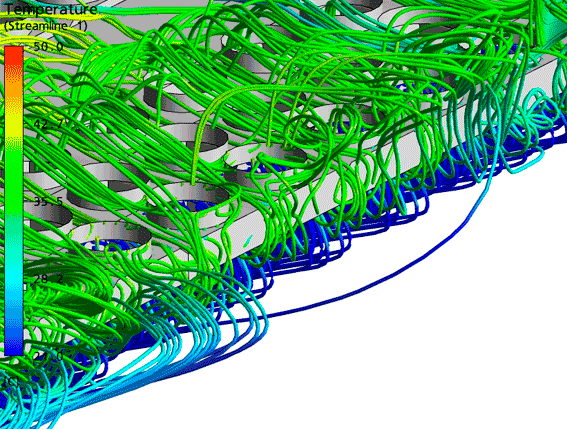

This article describes the preliminary study resulting in the design solutions adopted for the LAD module’s most important thermo-mechanical drivers, which were developed and used to demonstrate compliance with the system requirements at the spacecraft level. More specifically it describes the mechanical design of the module and its components, the results of a static, dynamic, and thermo-elastic finite element analysis of a simplified parametric model with accurate mesh processing, and the preliminary optimization of a critical component: the bipod.

Read the article