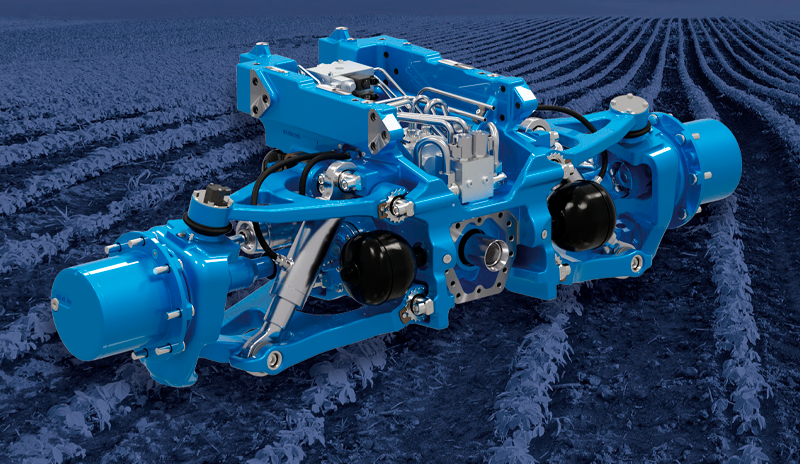

Powering the next generation of off-highway suspension design

Design process integration of an independent suspension axle for off-highway vehicles

Newsletter EnginSoft Year 18 n°2

By Alessandro Benevelli and Federico Bavaresco | DANA Incorporated

Andrea Fornaciari | University of Modena and Reggio Emilia

Alessandro Benevelli is a System Solution Engineer at Dana Incorporated (in Reggio Emilia, Italy) and Federico Bavaresco is an Axle Lead Engineer at Dana Incorporated (in Arco, Italy).