Pipistrel, an aviation and aerospace company based in Slovenia, chose ESTECO technologies to design the propeller for a highly efficient, hybrid-electric aircraft.

The work was part of the EU-funded project MAHEPA (Modular Approach to Hybrid Electric Propulsion Architecture), which aimed to advance two variants of a low-emission, serial, hybridelectric propulsion architecture to Technology Readiness Level (TRL) 6. modeFRONTIER process automation and optimization software enabled the simulation process to be automated so that innovative and optimized designs could be identified in a limited amount of time.

Read the article

CASE STUDY

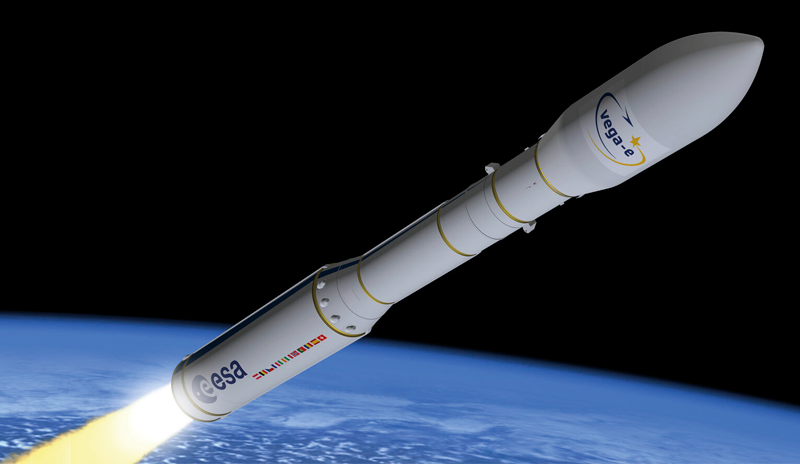

This article is based on a collaboration between RBF Morph and AVIO to configure a numerical optimization procedure to improve the Vega E M10 engine’s performance by optimizing the methane circuit of the injector head.

aerospace rbf-morph ansys meshing

CASE STUDY

This project has been coordinated by the German Aerospace Center (DLR) and it is embedded in the MELiSSA framework of ESA research projects.

aerospace cfd ansys