Abstract

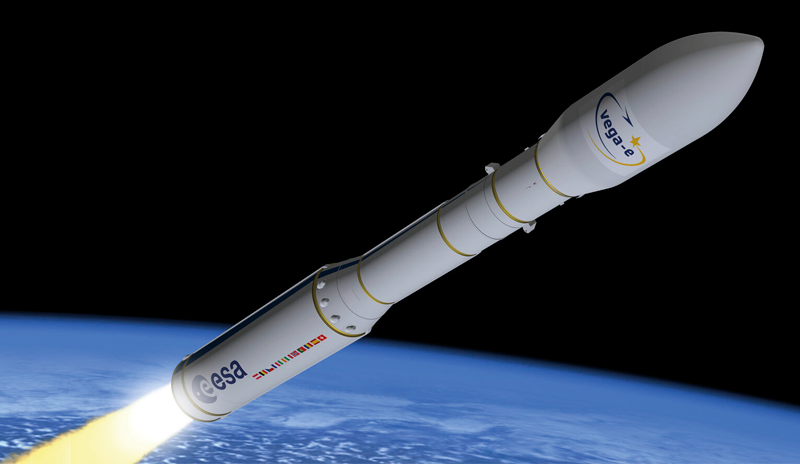

This article is based on a collaboration between RBF Morph and AVIO to configure a numerical optimization procedure to improve the Vega E M10 engine’s performance by optimizing the methane circuit of the injector head. Vega E (Evolution) is the new three-stage satellite launch vehicle (see above) for a project coordinated by ESA (European Space Agency) to qualify the Vega C’s successor. The Vega E’s maiden flight is scheduled for 2026.

The M10, which will use liquid oxygen and liquid methane as propellants, is a new-generation more environmentally friendly engine for the final stage of the launcher, and was developed and built by Avio in Colleferro in Italy. It is a 10-tonne LOX/LCH4-class cryogenic liquid rocket engine and is the first European engine to use methane. The design team, led by Avio, involves a consortium of companies from Belgium, the Czech Republic, Switzerland, France, Austria, and Romania. The design objective for this activity was to reduce the pressure drop between the inlet of the manifold and the outlet of the engine combustion chamber with a constraint on the maximum temperature of the firing plate.

Read the article