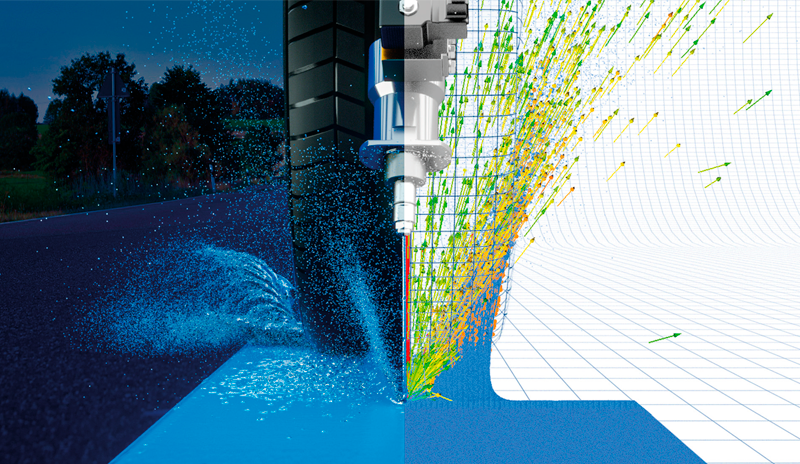

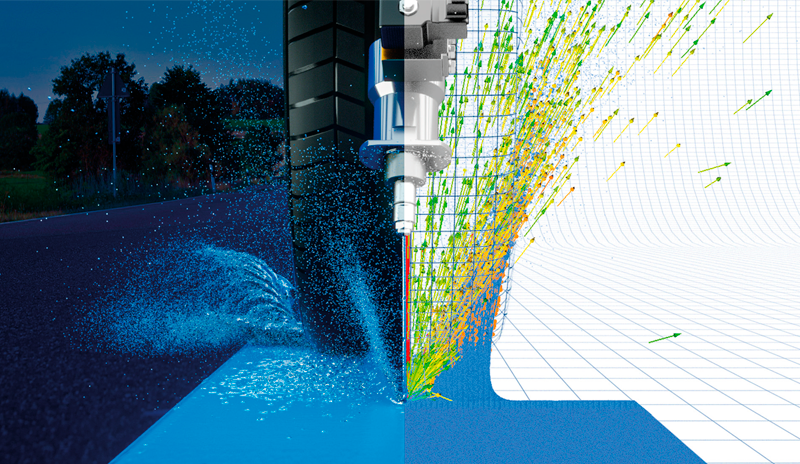

Optimization of water spray parameters by 3D CFD particle simulation for an automotive anti-aquaplaning system

Futurities Year 19 n°3

By Silvestru Chiriches, Paolo Alberto Fina - EASYRAIN | Michele Merelli - EnginSoft

One in four accidents in the United States (according to the National Highway Traffic Safety

Administration) is due to adverse weather conditions. The same study reports that wet

roads are more dangerous than icy and snowy roads (46% of accidents versus 30%).

Aquaplaning and hydroplaning occur when water, accumulated on the road surface or splashed

by vehicles ahead, forms a thin layer between the asphalt and the car tyre.

This layer prevents the tyre from properly adhering and gripping, making the

vehicle uncontrollable and often causing accidents.

In this paper, we discuss the digital

modelling and simulation of the EASYRAIN Aquaplaning Intelligent Solution (AIS)

using mesh-free moving particle simulation (MPS). We used MPS to study the impact

of the pressurized water jet of the AIS system.

First, we verified the jet forces predicted by the CFD methodology with experimental configurations and compared the

MPS results with the results of track tests.

Furthermore, we analysed the influence

of different working parameters (such as water jet pressure, spray angle and injector position)

on the efficiency of aquaplaning prevention.

Considering the speed of a car, it is important to take into account aerodynamic effects and their influence on the jet. For this reason, we used a finite volume solver embedded in the CFD software itself and fully coupled with the liquid phase MPS. Thanks to the reported validations and experimental correlations, EASYRAIN can thus design and improve the AIS system without the need for time-consuming physical prototypes and expensive track tests, resulting in the best solution for a wide range of car bodies and hydraulic systems.

Read the articlesoftware

Particleworks is an advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method.

particleworks

CASE STUDY

In this article, Del Negro explains how Ricardo is developing solutions to support its customers to predict the lifecycle of motorcycle components, using finite element analysis (FEA) and fatigue analysis.

femfat mechanics automotive