Abstract

An important cause of failure in machines with complex components is fatigue from vibration due to being subject to multiple forces that vary over time.

While these machines undergo extensive testing both at the bench and in the field, engineers need a generalized methodology to better calculate the fatigue

in the presence of any number of known loads in time for a given cycle, in order to improve the estimation of the components’ fatigue life and effectively integrate that

into the product development process.

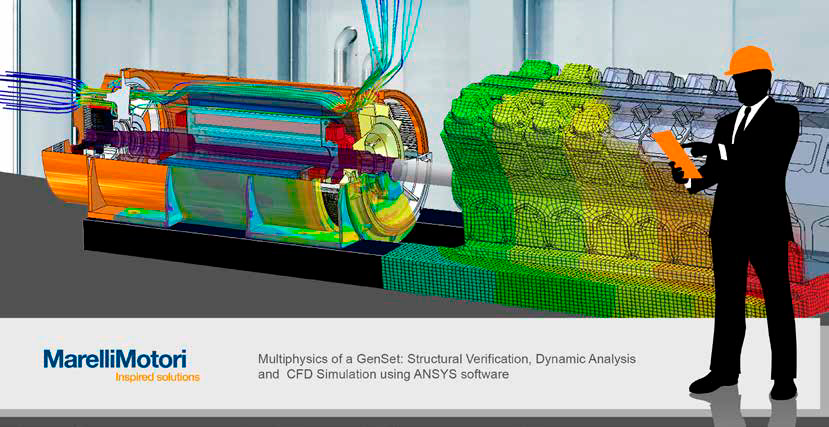

This technical article details the application of the methodology developed using ANSYS WorkBench.

Read the article