Lime Kiln DEM Analysis with ROCKY

CAE is key to ensuring the efficiency and technical integrity of equipment and plants in the lime industry

Newsletter EnginSoft Year 13 n°1

Process Engineering is fundamental to the development of industrial plants and includes all phases from site visits and surveys to issue identification and analysis and long-term project development. In the lime industry, the process engineers of Cimprogretti, a worldwide leader in the design of plants and equipment for the lime industry, design and optimize chemical processes, advise on process safety, analyse and interpret laboratory and plant data and provide specialised support to ensure the technical integrity of equipment and plants.

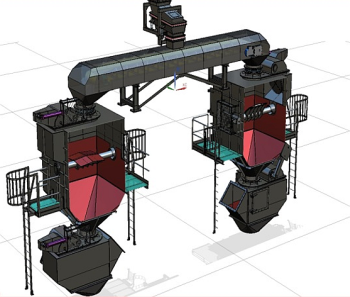

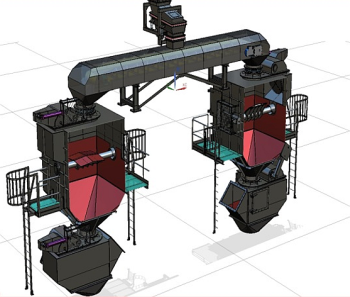

Specifically, Cimprogetti uses CAE to predict the behaviour of design solutions, testing innovations and optimizing designs from the earliest stages of conceptualization through to product validation and a better understanding of the implications of design decisions on plant performance. This brief article outlines how Cimprogetti and EnginSoft used ROCKY Discrete Element Modeling to perform a dynamic analysis of the entire lime transportation phase to improve the design of a new kiln loading system. An important part of the simulation was the calibration of the lime particles’ physical and geometrical characteristics in order to achieve uniform stone distribution.

Read the articlesoftware

Particleworks is an advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method.

particleworks

CASE STUDY

The text provides an in-depth account of Stefano Odorizzi’s journey in founding and growing EnginSoft, our engineering company specializing in computer simulation and modelling. Established in 1984, EnginSoft overcame early challenges, such as the high cost of computing, to emerge as a leader in simulation services, particularly in the fields of mechanical engineering and computational fluid dynamics (CFD). The narrative highlights several key milestones in the company’s history.

cfd metal-process-simulation industry4 news mechanics optimization