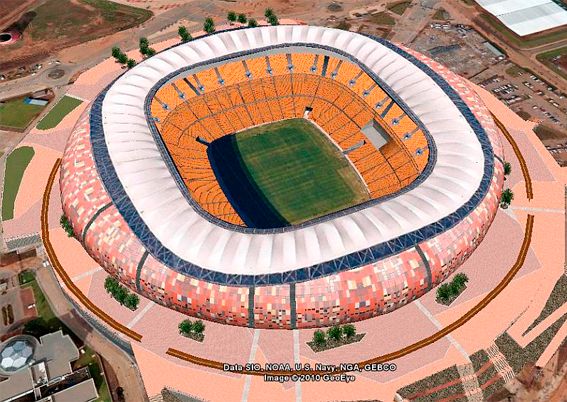

Johannesburg 2010 World Cup Stadium

Abstract

When the FNM stadium in Johannesburg was selected as the venue for the 2010 FIFA World Cup, an ambitious remodeling and expansion plan for the stadium was initiated.

The remodeled stadium which became known as Soccer City or the “Calabash” was to have its facade clad with a mosaic made of, earth and fire colored, light fiber-cement panels. The cantilever roof structure was to be clad with PTFE membranes matching the sand color of the mines found in the stadium neighborhood. Our study involved the virtual simulation of the roof and facade structures for the construction phase of the project on behalf of Cimolai Spa of Italy, the contractor for both the façade and roof.

The study analyzed these structures for strength, service and stability conditions before construction.