How to optimize an external gear pump in highly constrained conditions

Meeting the engineering challenge of increasing efficiency while reducing costs

Newsletter EnginSoft Year 14 n°1

By Manuel Rigosi | Casappa

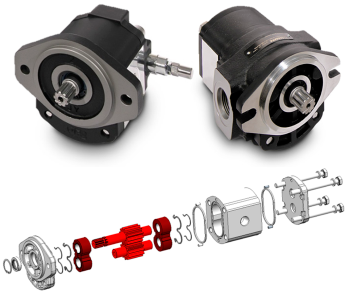

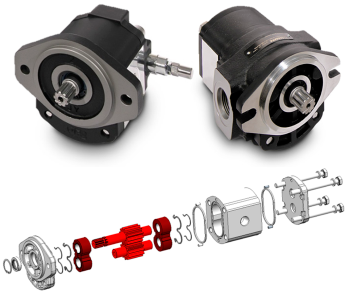

In this technical case study, EnginSoft assists Casappa to further refine the core feature of an already optimized gear pump in order to achieve best performance in terms of efficiency and reduction of noise emission while maintaining its same level of performance. The approach adopted was to review the core feature of the pump -- the design of its gears and the interfacing lateral plates -- in order to reduce the overall noise generated by the internal oscillating forces inside the pump and by the pressure fluctuations. Since the expected performances are always higher in respect to previous versions, while complying production needs, this kind of problem becomes highly constrained.

This article details the steps and procedures followed to apply, two different ModeFRONTIER genetic algorithms: Multi-Objective Genetic Algorithm (MOGAII) versus Multi-Objective Game Theory (MOGT) to find and then test the best virtual redesign and best algorithm, in order to create a prototype for physical testing in the laboratory.

Read the article

CASE STUDY

In this case study, EnginSoft engineers explain how they used modeFRONTIER to assist Comau, a Fiat Chrysler subsidiary, to optimize their approach to the preliminary design of production systems for automotive manufacturing system RFQs.

automotive optimization rail-transport modefrontier SIMUL8 iphysics industry4

CASE STUDY

Elettronica SpA designs and produces systems for electronic warfare. Each system design is unique according to its platform and purpose. In this article, the company describes how it used CAE to approach the challenging design of a single sandwich radome.

ansys optimization electronics