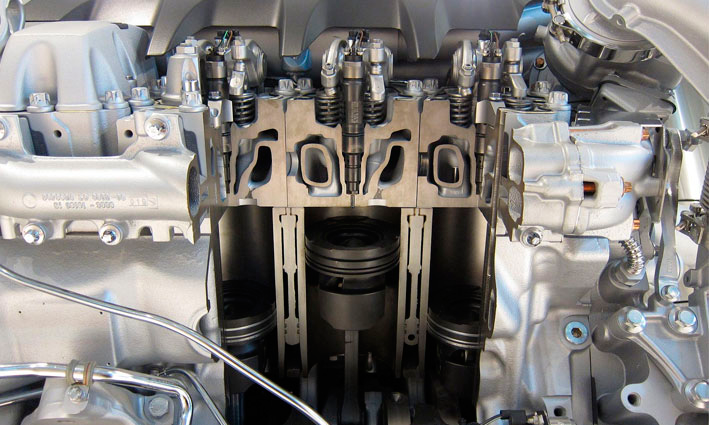

Fuel Injection

Fuel injectors are subjected to extremely rapid movements due to the necessity of spraying the fuel into the combustion chamber in less than a millisecond.

A multibody model was developed using RecurDyn to study the high-speed dynamic behavior of the injector during a typical work cycle. The model contains both rigid and flexible bodies: the pin was modelled using the proprietary Full Flex technology which includes a Finite Element body in the dynamic simulation. This option permits users to evaluate the influence the flexibility has on the body’s motion, and to calculate the stress on the component. The spring was modelled using beam elements to correctly represent its inertial properties, and the contact between the coils.

Together, these elements create a reliable numerical model that can be used to evaluate the positions of the bodies, and the contact forces between the pin and the housing, in order to predict the performance of the injector.