Abstract

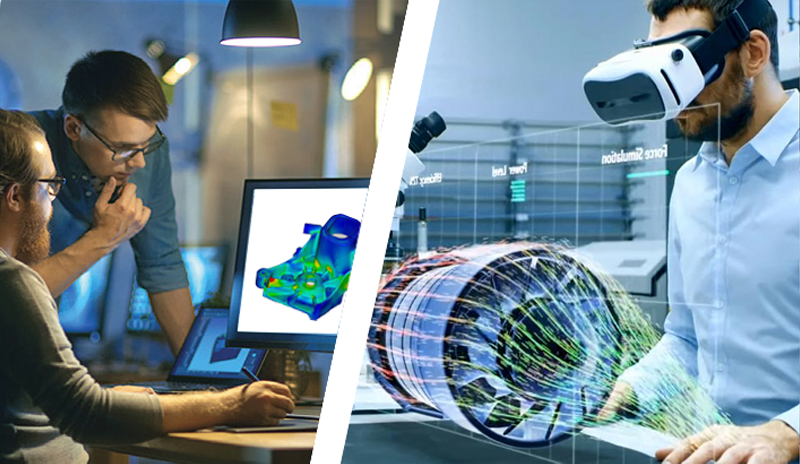

Faber Spa, which has designed and manufactured ventilation hoods for the past 50 years, holds a key global position both in terms of production and technology. It has achieved this position through strategic investments in research and development, which have just recently been further strengthened through the addition of Finite Element Method (FEM) tools, particularly the ANSYS software platform. In this technical article, the engineers describe how they applied FEM methods – including fluid dynamics, structural analyses and thermal analyses – to refine a hood’s ventilation systems, predict the appliance’s performance in a drop test, and predict the behaviour of the plastic molded parts under normal operating conditions.

In addition to these performance improvements, further objectives for the FEM approach were to reduce the time to market and the product costs while increasing the quality and the structural reliability of the hoods. Faber explains that this integrated development approach to product planning, using simulation, enabled them to produce more solutions in less time and at less cost compared to an experimental approach.

Read the article