ECM Technologies has significantly streamlined the design, installation, and commissioning of its large-scale heat treatment systems for the automotive industry by using digital twin technology and Rockwell Automation's Emulate3D software.

Faced with tight timelines and software compatibility challenges during a major project in Mexico, ECM used virtual models to simulate and test their systems in parallel with production.

This approach reduced commissioning time by 50% and saved up to five months in lead time. The success of the project has led to follow-up orders and a broader adoption of digital twin technology across ECM’s operations. The company now uses Emulate3D to manage multiple projects more efficiently, cutting down on on-site work, improving team productivity, and increasing confidence in meeting project deadlines.

Read the articlesoftware

Emulate 3D is an advanced digital twin software that enables users to create accurate virtual replicas of their industrial automation systems. This powerful tool allows for comprehensive testing, simulation, and emulation of systems before they are physically constructed, providing significant advantages across various industries, including material handling, manufacturing, and automation.

industry4 optimization digital-manufacturing rockwell emulate3d

CASE STUDY

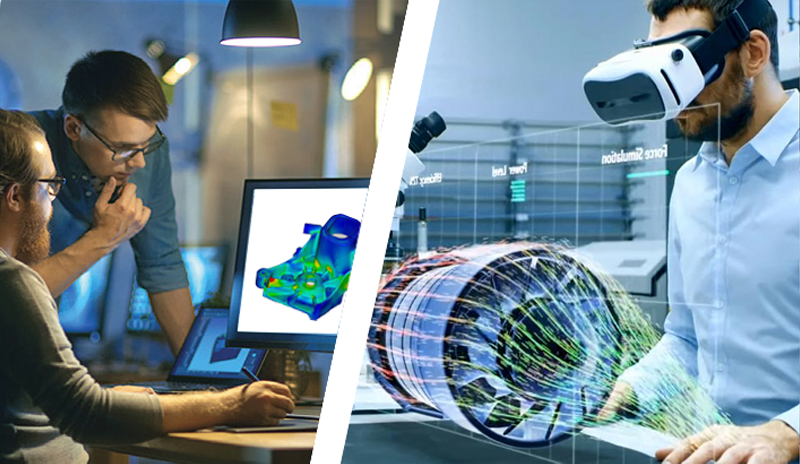

At this particular moment in time, this article wishes to reflect on the evolution of CAE and simulation in an effort to present a big-picture view when most of us are daily dealing with all the devil in the details in every aspect of our lives. We approached some long-standing business friends in engineering simulation from various regions around the world to help us in this task

ansys industry4 news