This technical article describes a project that was undertaken by TAE SUNG Software and Engineering, in collaboration with DY AUTO in Korea, to establish a computerized process to conduct three-dimensional real-scale analysis of any of the three types of windshield wiper currently in use, and to establish a specific standard for evaluating wiper performance.

It describes the procedure that was followed to model wiper performance, to collect data about that performance in terms of friction, wiping speed and contact pressure, and to develop a user-friendly pre- and post-processor for the developed program to facilitate the creation of analytical models to evaluate wiper performance and to analyze the results.

Read the articleCASE STUDY

The adoption of SBES has significantly increased in the last two decades, driven by advancements in computing technology and the rise of Industry 4.0, which promotes nine key enabling technologies, including engineering simulation and big data analytics. SBES is crucial for the integration and automation of production systems, improving flexibility, speed, and quality.

automotive construction energy cfd metal-process-simulation

CASE STUDY

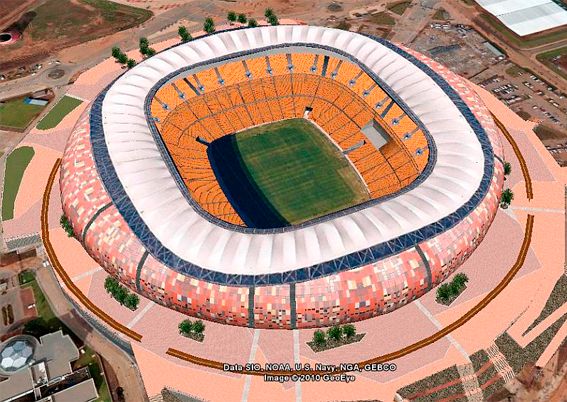

The study analyzed these structures for strength, service and stability conditions before construction.

civil-engineering construction ansys