This paper presents the main steps taken in the development phase of the IVECO cab suspension brackets to comply with the new ECE R29 crash regulation for Heavy Commercial Vehicles (HVC). In this study, modeFRONTIER drives and guides different CAE software (Hypermesh, Radioss, Nastran and MATLAB) to fulfil all the requirements for the component under examination. The IVECO cab suspension brackets are actually designed to deform considerably during the ECE R29 tests, while still being strong enough to survive the IVECO fatigue mission without any failures.

These are two opposing goals: a typical challenge for optimization software like modeFRONTIER.

Read the article

CASE STUDY

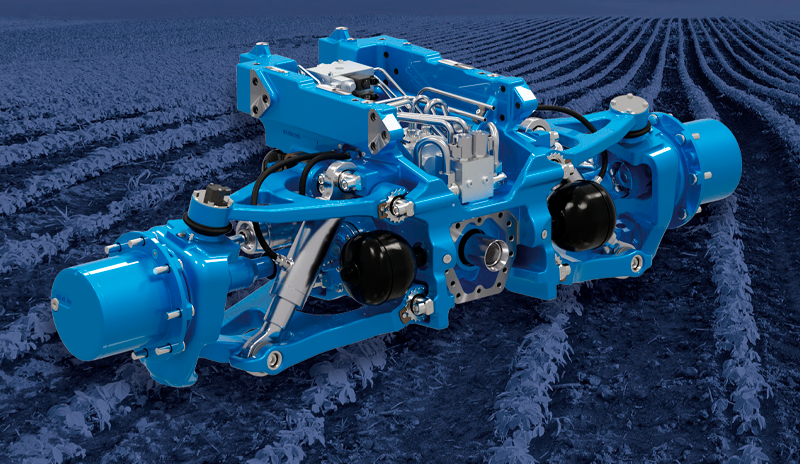

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization

CASE STUDY

This article describes an analysis of the performance of a hot water distribution piping network consisting of a main boiler and various utilities inside an automotive paint shop based in France. The simulation is performed using Flownex, a CFD (computational fluid dynamics) software with concentrated parameters.

automotive flownex