Abstract

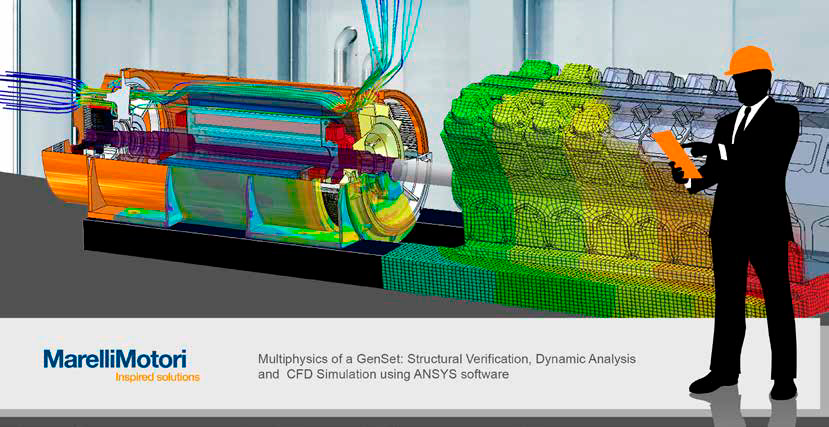

Improving efficiency while reducing cost is a very complex engineering challenge. Marelli Motori, one of the world’s leading generator and electric motor manufacturers, makes extensive use of Computational Fluid Dynamics (CFD) and Finite Element Method (FEM) multiphysics simulation to do just that in the design of its electrical motors and generators. It applies CAE to help it achieve the goals of increasing the efficiency and reliability of its products and lowering their environmental footprint as much as possible, reduce the product development costs in order to remain competitive and keep the products “sellable”, while shortening the time to market. In this overview article, EnginSoft engineers describe how the challenge is approached by using multiphysics simulations for all the components of the motors and generators, as well as to the construction operations.

Read the article