Cimolai Technology chooses Ansys

Cimolai Technology designs and produces special machines and plants for lifting, handling, transport and launching operations

Newsletter EnginSoft Year 14 n°1

Cimolai Technology, based in Carmignano di Brenta near Venice, designs and produces special machines and plants for lifting, handling, transport and launching operations. The company works closely with customers to find the right solution for any specific field and application. All machines are produced, pre-assembled and tested in the company’s state-of-the-art facility which enables Cimolai Technology to offer short delivery times and guarantee a high quality 100%-Italian products.

In order to allow it to continue offer regulation-compliant, customized solutions to meet customer requests, Cimolai Technology opted to replace its previous computation system with ANSYS Workbench and Space Claim software. In this brief article, the company explains the business benefits it has achieved since the installation in terms of time savings in planning, and design, and improvements in product quality and in delivery forecast ability.

Read the articleCASE STUDY

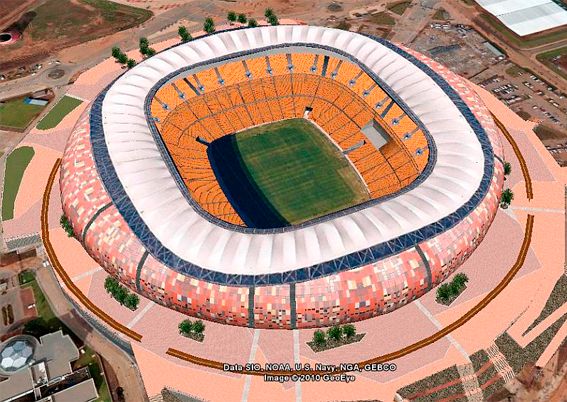

Read the fascinating articles on the vast subject of structural engineering, beginning with a philosophical bent and arguing for the necessity of a skillful and artful intertwining of Engineering, Numerical Simulation, Art and Technology to achieve structures that are both eminently functional yet attractive and appealing.

civil-engineering

CASE STUDY

The study analyzed these structures for strength, service and stability conditions before construction.

civil-engineering construction ansys