CFD analysis for the evaluation of the air flow within a climate control unit

Considering the value of numerical analysis for new product design

Newsletter EnginSoft Year 12 n°1

By Ufficio Sviluppo Prodotti Climaveneta

Climaveneta SpA enlisted the support of EnginSoft to assess the possible advantages of using Computational Fluid Dynamics (CFD) analysis in its new product design process. The objective of the study was to create a virtual model of Climaveneta’s new ACU171 Expanded Close Control Unit and then match the numerical results with the experimental measures. Afterwards, the engineers tested some geometric modifications to optimize the distribution of the air flow velocity on the filter surface to improve the unit’s heat exchange properties. This brief technical article describes how the study was undertaken and the results obtained.

Read the articleCASE STUDY

The adoption of SBES has significantly increased in the last two decades, driven by advancements in computing technology and the rise of Industry 4.0, which promotes nine key enabling technologies, including engineering simulation and big data analytics. SBES is crucial for the integration and automation of production systems, improving flexibility, speed, and quality.

automotive construction energy cfd metal-process-simulation

CASE STUDY

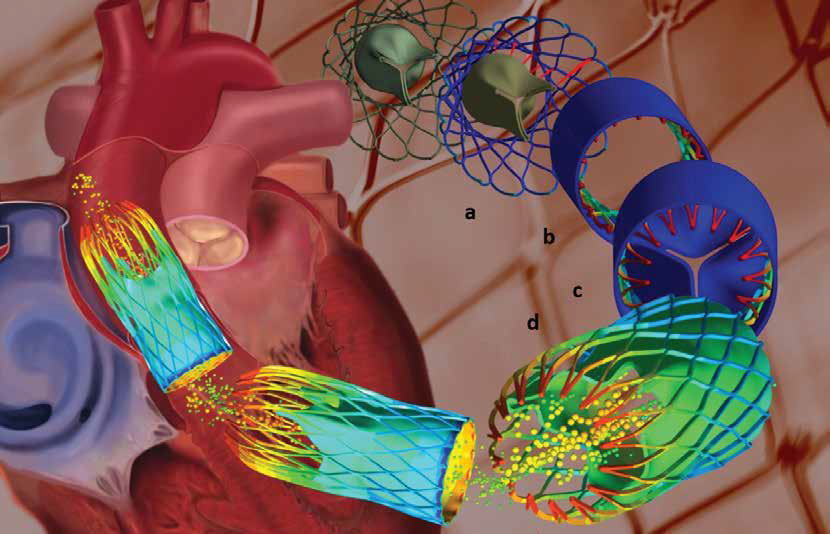

Since this cannot be accurately measured in an implanted stent, manufacturers decided to use Multiphysics to simulate the process to better understand the method and to calculate the forces operating on the implant in order to improve the stent design and the surgical procedure, as described in this article.

cfd biomechanics ansys