Aviospace: The Italian Aerospace & Defense Company | Interview with Eng. Giovanni Gambacciani

Using simulation for engineering challenges in unknown or poorly understood environments

Newsletter EnginSoft Year 14 n°3

Aviospace is an Italian company founded in 2004, active in the Aerospace & Defense industrial sector. The company headquarters is in the centre of Turin and employs about twenty people: most of them are qualified and skilled engineers, who work on the development of Aerospace Systems, from the conceptual phases, research and development, to the prototypes and flight parts, in partnership with major international agencies. We met with Aviospace engineer Giovanni Gambacciani to learn about the essence of Aviospace and the challenges it faces in industry.

Gambacciani’s enthusiasm towards his work and the industry is evident after the first question. Almost 40 years, since he graduated, with full marks at the University of Florence, as a mechanical engineer, Gambacciani began his career in development of diesel engines at FIAT-GM Powertrain (now FCA) where he gains a solid experience on CAE both in the fluid and structural environment.

Read the articleCASE STUDY

The text provides an in-depth account of Stefano Odorizzi’s journey in founding and growing EnginSoft, our engineering company specializing in computer simulation and modelling. Established in 1984, EnginSoft overcame early challenges, such as the high cost of computing, to emerge as a leader in simulation services, particularly in the fields of mechanical engineering and computational fluid dynamics (CFD). The narrative highlights several key milestones in the company’s history.

cfd metal-process-simulation industry4 news mechanics optimization

CASE STUDY

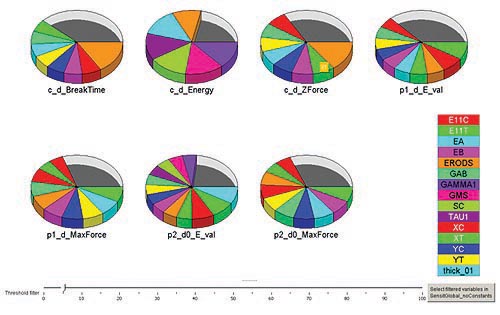

While the engineers relied on modeFRONTIER's capabilities, the procedure has been to calibrate the constitutive parameters of LS-DYNA's advanced material models, and to use them for prediction, design optimization and robustness analysis.

modefrontier ls-dyna automotive composites