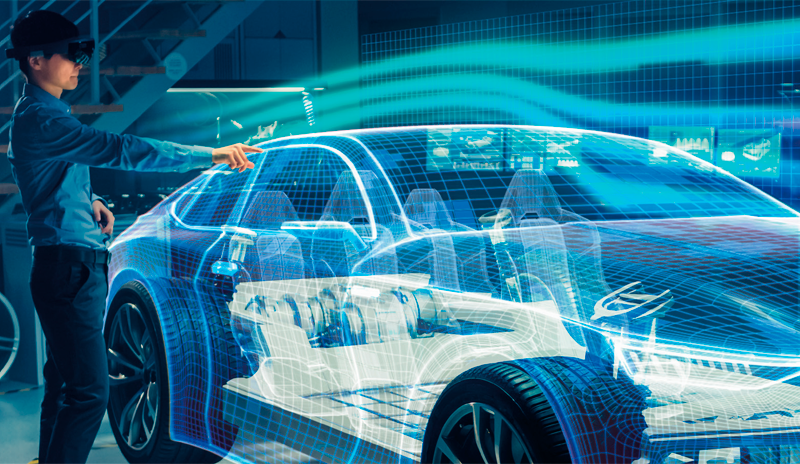

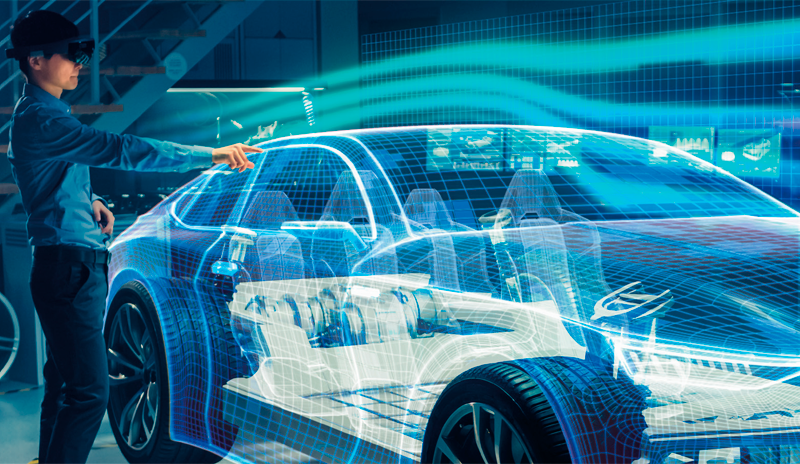

A perspective on simulation in the automotive industry

Face to face with Paul Stewart, design process leader and consultant

Futurities Year 20 n°2

By Kathleen Grant

Dr Paul Stewart qualified as a Systems Design Engineer in naval architecture and currently consults on design process both with CAE providers and with Design and Engineering companies. He has a solid foundation in CAD surface mathematics and fluid dynamics as they relate to the design process. He began his working career at the Ford Research Lab where he was the first to apply shape morphing to automotive CFD (computational fluid dynamics) and then continued on with EXA and eventually Altair, creating virtual design technologies involving advanced surface modelling, response analytics, and advanced visualization. During this time, he has worked on production design projects and processes with almost every automotive and heavy truck manufacturer worldwide.

Futurities interviewed him about his thoughts on the evolution of simulation’s role in the design process in the automotive industry, the evolving roles of CAD and CAE and the move to freeform deformation in automotive design, as well as the likely impact and role of artificial intelligence technologies in this space.

Read the articleCASE STUDY

The article discusses advancements in low cycle fatigue analysis for an electric motor's rotor, focusing on a new method implemented in the FEMFAT software. Traditional methods have limitations in accurately predicting material plasticization due to a lack of consideration for the sequence of load peaks, which can affect component lifespan.

automotive femfat