Gamma Meccanica’s R&D department is constantly researching new solutions to improve the overall performance of equipment, production capacity and reliability while developing environmentally sustainable processes and applications to benefit its customers.

This paper presents a numerical model for a melting furnace for

stone wool. The numerical model was designed using Ansys Fluent. The model includes all the main aspects of the real

process (the electrical field, the heat transfer process and the fluid

dynamics of the melt).

The CFD simulation provided a lot of information about the

operating conditions of the electric melter while considering the

hypothesis of the dissipation terms. A proper validation on site

in the field will enable us to obtain a more reliable setup of the

model, to reflect reality as closely as possible.

CASE STUDY

The text provides an in-depth account of Stefano Odorizzi’s journey in founding and growing EnginSoft, our engineering company specializing in computer simulation and modelling. Established in 1984, EnginSoft overcame early challenges, such as the high cost of computing, to emerge as a leader in simulation services, particularly in the fields of mechanical engineering and computational fluid dynamics (CFD). The narrative highlights several key milestones in the company’s history.

cfd metal-process-simulation industry4 news mechanics optimization

CASE STUDY

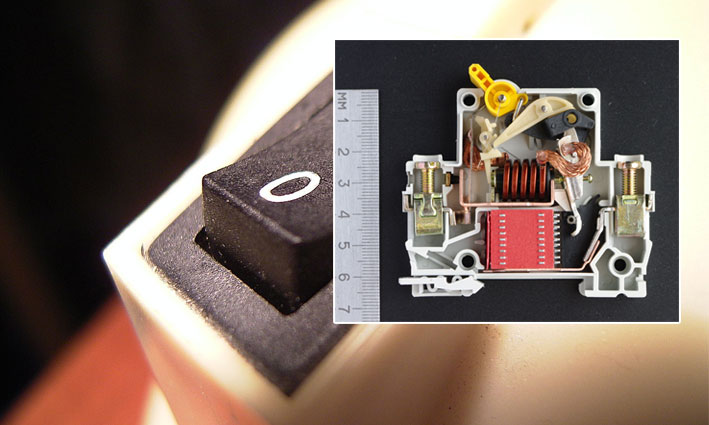

The premium software RecurDyn was used to simulate a Double Pole Single Throw Switch using three different modeling schemes. A comparison of the results provided useful information for the designers.

recurdyn mechanics multibody