CASE STUDY

This article presents an example of a proposed design optimization approach with a case study.

biomechanics modefrontier

CASE STUDY

This article describes an analysis of the performance of a hot water distribution piping network consisting of a main boiler and various utilities inside an automotive paint shop based in France. The simulation is performed using Flownex, a CFD (computational fluid dynamics) software with concentrated parameters.

automotive flownex

CASE STUDY

A lot of steel structures such as cranes, heavy machinery and other equipment subjected to repetitive loading is highly likely to develop cracks or failures because of the fatigue damage. The cost of every hour of equipment downtime is usually very expensive, making it mandatory to perform residual life calculations or fatigue checks.

ansys energy

CASE STUDY

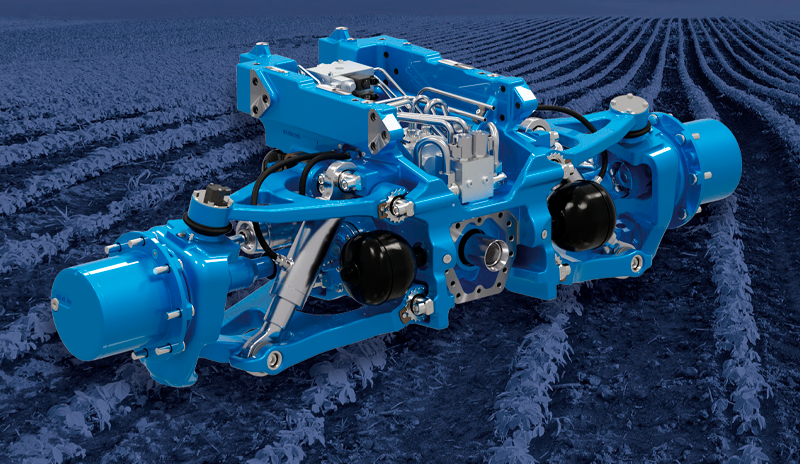

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization

CASE STUDY

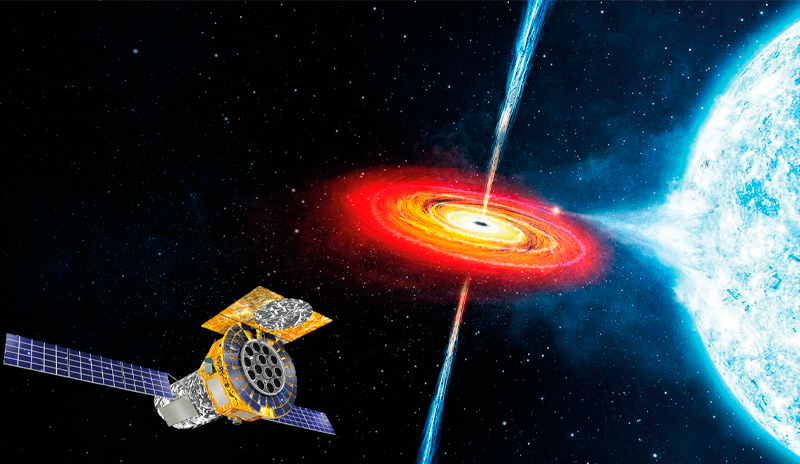

This article describes the preliminary study resulting in the design solutions adopted for the LAD module’s most important thermo-mechanical drivers, which were developed and used to demonstrate compliance with the system requirements at the spacecraft level.

aerospace rbf-morph ansys

CASE STUDY

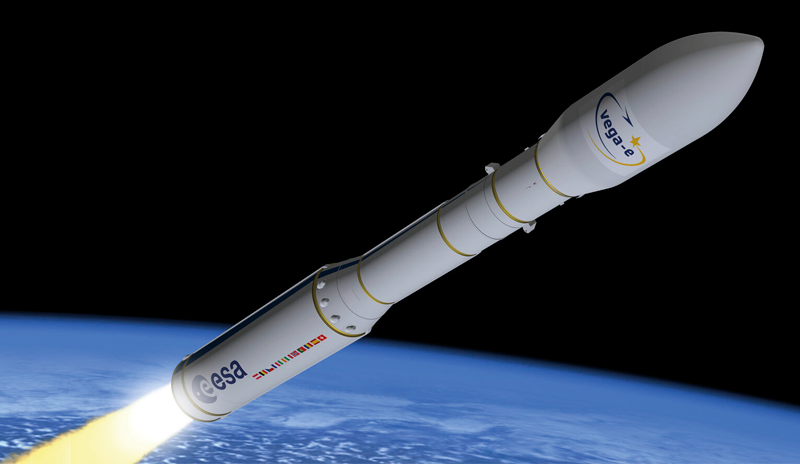

This article is based on a collaboration between RBF Morph and AVIO to configure a numerical optimization procedure to improve the Vega E M10 engine’s performance by optimizing the methane circuit of the injector head.

aerospace rbf-morph ansys meshing

CASE STUDY

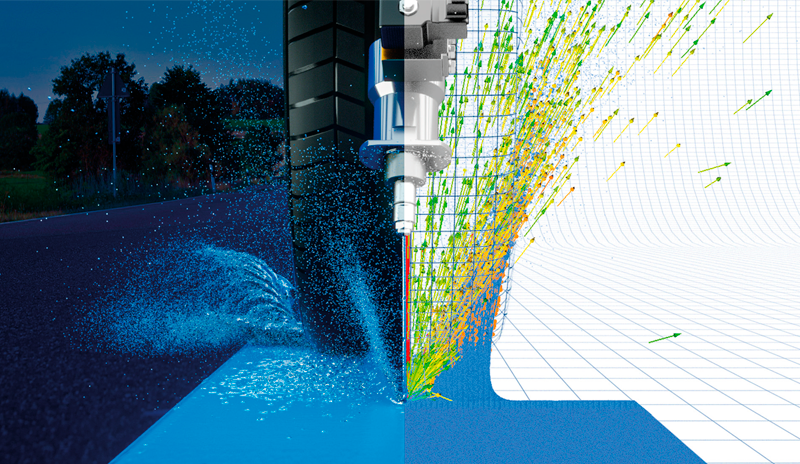

In this paper, we discuss the digital modelling and simulation of the EASYRAIN Aquaplaning Intelligent Solution (AIS) using mesh-free moving particle simulation (MPS).

automotive particleworks

CASE STUDY

In this paper, we will present the methodology developed by TotalEnergies and EnginSoft to select, design and improve an e-motor by simulating and predicting electromagnetic losses, fluid flow behaviour and temperature distributions.

automotive electronics particleworks

CASE STUDY

Material models used in structural finite element analysis (FEA) are often one of the key aspects that engineers need to describe very accurately.

optimization modefrontier ls-dyna

CASE STUDY

This article discusses the use of moving particle simulation of the oil distribution system to predict heat dissipation and temperature distribution in the engine in order to examine virtual e-drive prototypes to improve their final design.

particleworks automotive

CASE STUDY

This article combines the use of the finite element method with a Design Thinking approach to reconstruct a road traffic accident for an traffic accident insurance report in order to analyse the outcome of the accident, compare the respective property damage, and the physical injuries to pedestrians or passengers in order to limit the quantity of large claims compensation for the insurance company, while ensuring the fairness of the compensation for the customer to foster greater trust and credibility in the insurance provider.

automotive ls-dyna

CASE STUDY

This article describes how EnginSoft applied a Computational Fluid Dynamics (CFD) analysis, on behalf of Whirlpool EMEA, to simulate three different geometrical design modifications to the vacuum cleaner head to improve on a baseline performance that was modelled first.

appliances cfd ansys