The energy scenarios and the reduction of greenhouse gas emissions underlie the development and extensive use of technology that makes the proposed goals possible. This development requires both heavy investment in research and development (public and private), and incentive policies to achieve economic self-sustainability. Precisely this requirement means that the countries should ask themselves and give clear indications of, what must be done and which technology should be deemed as a priority.

In this context the European Commission has developed a Strategic Energy Technology Plan that brings technological innovation to the center of strategies to reduce greenhouse gas emissions and ensure the security of energy supply.

The development and subsequent industrialization of all these new technologies, from the technical and scientific point of view, requires and will require in the coming years a huge commitment of intelligence, first-class technical skills, and tools for designing components and systems in the best ways.

In this context, CAE Technology and Intelligent Digital Prototyping (iDP) hold, and will increasingly hold, an absolutely determining role in whether the project ideas can be tested, optimized and validated before prototypes are built.

EnginSoft is a company that has based its competitive advantage on virtual prototyping since the 1980es, and has always been diligent in the training and formation of its technical staff in order to provide companies with the best solutions and the most suitable software for their specific needs.

EnginSoft’s strength is the multidisciplinary approach that includes all areas of Computer Based Engineering, from the manufacturing process to the detailed 3D CFD simulation of power generation components such as turbines, compressors, heat exchangers, and more.

CASE STUDY

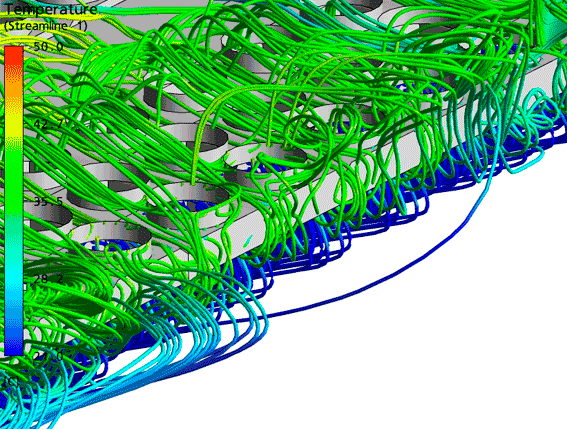

EnginSoft developed a 3D CFD model of a Liquefied Natural Gas (LNG) Plant for the simulation of the Air-Cooled Heat Exchanger Systems’ (ACHE) arrays and their interaction with the wind.

energy cfd ansys oil-gas

CASE STUDY

The article discusses the importance of understanding the behaviour and performance of batteries under different operating conditions, particularly in the context of large-scale adoption of batteries. The hybrid approach has successfully identified the Goldilocks Zone for electrochemical parameters and provides a good match between predicted and experimental data.

automotive oorja energy

CASE STUDY

The article discusses advancements in all-solid-state batteries (ASSBs) as safe energy storage solutions, highlighting the challenges in achieving high ion conductivity compared to conventional lithium-ion batteries (LIBs). While ASSBs offer safety and high energy density, issues such as internal resistance and low ionic conductivity hinder their performance.

energy multiscale

CASE STUDY

This technical article describes a numerical (transient computational fluid dynamics) simulation applied to study the suction efficiency of a canopy hood in a steel plant’s electric arc furnace with a view to increasing it.

ansys energy

CASE STUDY

This technical article describes a project led by BLOM Maritime under the auspices of the HS-03 SNAME (the Society of Naval Architects and Maritime Engineers) panel in which ESTECO’s modeFRONTIER process automation and design optimization software was used to optimize the design of a monopile for a 15MW turbine to survive hurricane conditions.

modefrontier energy

CASE STUDY

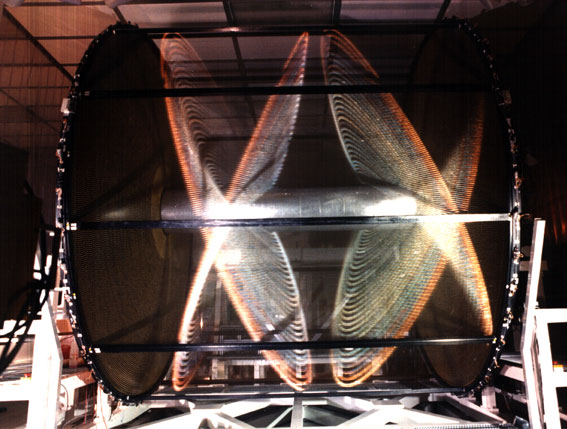

EnginSoft’s cost-effective solution was successfully created in collaboration with F4E’s expert teams after numerous years spent developing and testing tools, algorithms and customized interfaces in each phase of the Electromagnetic FEM analysis workflow.

energy ansys electronics

CASE STUDY

GE Power is a world leading supplier of solutions for power generation, from engineering to manufacturing. Detecting and mitigating critical flow structures in water pumping stations is a complex engineering task, that has always been based on experimental activities. Now GE Power can rely also on CFD modelling and on the support of EnginSoft

ansys cfd energy

CASE STUDY

This article describes how SAER ELETTROPOMPE used Ansys CFX to transform "standard" pumps into pumps to be used as turbines.

energy ansys cfd

CASE STUDY

By taking advantage of EnginSoft experience in Simulation Based Engineering, by means of the FEM analysis, the Durability, Structural Integrity and Buckling behavior of a new group of toxic liquid and fuel storage tanks have been investigated.

energy mechanics ansys

CASE STUDY

This article describes the Multiphysics optimization procedure undertaken to ensure the best compromise between electromagnetic and structural compliance for the Toroidal Field coils of the Advanced Divertor Configurations of the toroidal chamber, that holds the plasma in which the fusion reaction takes place.

energy ansys rbf-morph

CASE STUDY

The ITER reactor’s electron cyclotron heating and current drive (EC H&CD) system launcher requires an effective cooling system due to the strong thermal loads it supports. In supporting the design of this cooling system, NINE performed several numerical studies using the Ansys simulation tools

ansys energy

CASE STUDY

Marelli Motori engineers use Ansys multiphysics solutions to custom-design motors and generators to solve challenges in hydropower, cogeneration, oil and gas, civil and commercial marine transport, military applications, and ATEX applications involving motors and generators in explosive atmospheres, among other applications.

automotive ansys energy

CASE STUDY

This technical article presents a study to design a device that operates entirely on the principle of trapped vortices that intrinsically improve the mixing of hot combustion gases with fresh mixture, a characteristic that is essential both to diluted combustion and to Moderate or Intense Low-oxygen Dilution (MILD) combustion.

ansys cfd turbomachinery energy oil-gas

CASE STUDY

This article details a study that was undertaken by Castel, a producer of refrigeration and air conditioning components, to compare the results of an experimental method for testing expansion valves with a numerical method using Ansys.

ansys energy

CASE STUDY

Two main reasons have been the drivers for introducing and using CAE simulation technologies and mathematical modeling: safety and achieving optimal design.

ansys energy

CASE STUDY

A lot of steel structures such as cranes, heavy machinery and other equipment subjected to repetitive loading is highly likely to develop cracks or failures because of the fatigue damage. The cost of every hour of equipment downtime is usually very expensive, making it mandatory to perform residual life calculations or fatigue checks.

ansys energy

CASE STUDY

This work presents the CFD model of an axial piston pump and compares it to a validated 0D model. The main objective of this study was to analyze the flow field inside the pump, focusing on the aspects that involved the main inner volumes, such as the filling and emptying dynamics in the piston chambers and the flow field inside the ducts.

ansys cfd energy

CASE STUDY

This technical article describes a comparative study that was undertaken by Intermarine, with the assistance of EnginSoft, between using the Flownex simulation environment and Intermarine’s manual or classic methods (both of which were compared with actual field data from on-board measurements) to predict pressure losses in the various piping systems that convey fluids on board a vessel.

marine energy oil-gas flownex

CASE STUDY

A developer of innovative equipment designed a system to simplify the towing and laying down of marine pipelines in shallow water fields.

energy modefrontier optimization oil-gas recurdyn

CASE STUDY

In this technical case study, EnginSoft was called in to assist in the application of Computational Fluid Dynamics (CFD) to model the flame size of a regeneration gas-fired heater for a project in Oman.

ansys mechanics energy oil-gas

CASE STUDY

The ultimate goal of the study was to optimize the Drift Chamber’s performance in terms of stiffness, strength and weight o be mounted on the Mu2e particle detector at FermiLAB in Chicago

construction modefrontier ansys optimization energy

CASE STUDY

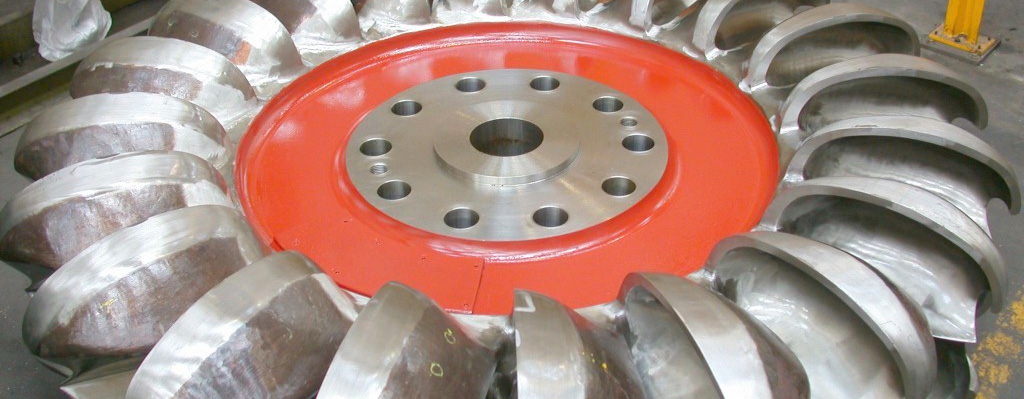

EnginSoft developed a Computational Fluid Dynamic (CFD) analysis methodology for the performance evaluation of a Pelton turbine

energy cfd ansys oil-gas

CASE STUDY

In this article, we show that the main turbine characteristics, such as efficiency and exit flow angle, can be sufficiently improved using parametric optimization.

modefrontier energy optimization

CASE STUDY

This technical paper presents an analysis process to accurately examine the environmental loads and structural stability of a Floating photovoltaic (PV) power plant. The method includes a hydrodynamic analysis of the Floating PV in its water-based environment as well as a structural analysis of its structural stability based on the characteristics of motion it undergoes.

ansys energy

CASE STUDY

In this technical article, we demonstrate how to apply a one-way coupling technique using a combination of ParticleWorks and LS-DYNA to estimate tsunami damage to a vehicle.

automotive ls-dyna energy cfd particleworks environmental

CASE STUDY

This technical article, a collaboration between EnginSoft and ZECO, compares two different methodologies for the study and optimization of impulse turbines, specifically Pelton turbines, in order to evaluate which is the quicker and more reliable method.

cfd particleworks energy